Professional Plastic Pipe Fitting Mould Manufacturer With 20 Years Of Experience - Spark Mould

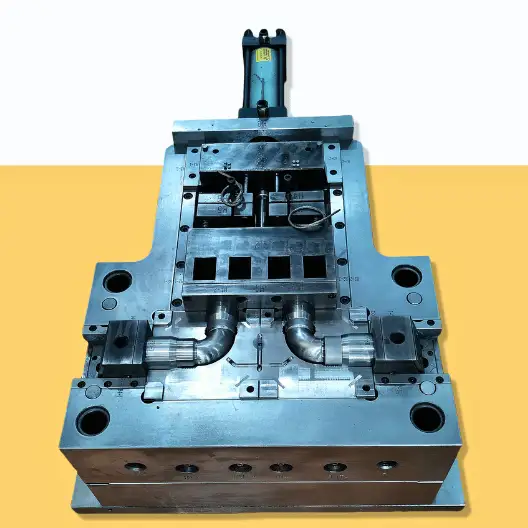

2-Cavity Collapsible Core PVC 90 Degree Elbow Mold

This custom 90 degree elbow mold originated from a challenge presented by our South African client. They were previously seeking a collapsible core mold structure solution for PVC 90° elbow. Until they saw a similar injection mold structure video on our YouTube channel (video link). While there are many solutions for 90 degree elbow pipe fittings, this collapsible core mechanism is the simplest yet most challenging. In this article, we will discuss the advantages and disadvantages of these mold structures. Let's dive in.

Before we begin, let me briefly introduce this project. This 90-degree elbow is made of PVC. It's part of a P trap, typically connected via a union to a J bend (J bend fitting mold example). The owner of this mold is one of South Africa's largest manufacturers of pipe and water management products. We have the capability to serve large clients. If you also need injection molds for P trap pipe fittings, feel free to contact us. We offer free engineering consultations and leverage our experience to provide you with the optimal pipe fitting mold solution.

How to design a 2-cavity collapsible core 90 degree elbow mold?

This 90-degree elbow mold has significant advantages but also fatal flaws. Of course, we also have our own solutions for the defects. In the following sections, we will analyze this mold from the aspects of its core-pulling mechanism, gate, runner, cooling system, and molding cycle.

Core Pulling Mechanism For 90 Degree Elbow Mold

This 90 degree elbow mold uses a collapsible core mechanism. It achieves core separation from the product without the need for a complex rotating mechanism. This segmented folding core mechanism consists of a wire rope, guide rail, hydraulic cylinder, and arc-shaped core, as shown in the diagram. The hydraulic cylinder is the driving unit, the arc-shaped core moves along the guide rail, and the wire rope is an auxiliary and connecting device. The collapsible core mechanism operates through the interaction of these four parts. When the core needs to be tightened, the various parts act like a tug-of-war. During the core-pulling action, the arc-shaped core moves along the guide rail. The core has grooves at a specific angle inside; as it moves along the guide rail, it changes a certain angle.

We'll stop here regarding the core-pulling mechanism, as a separate article will explain the design of 90 degree elbow mold in detail. While the principle behind this folded core structure is simple, the actual mold manufacturing process is quite challenging. We also experienced failure on our initial attempt. If you lack experience in manufacturing such 90-degree elbow molds, feel free to contact us. We have produced hundreds of these molds, and with our experience, we can help you achieve success.

90 Degree Elbow Mold Runner and Gate Design

In designing this 90 elbow mold, we adopted a submarine gate. It's a modified point gate where the gate is submerged in the mold plate below the parting line, connecting to the cavity in an inclined tunnel shape. The submarine gate combines the advantages of point gates and side gates, and the ejection system automatically cuts off the gate during mold opening. This perfectly meets the customer's requirements for automated production.

This 90-degree elbow mold uses a cold runner system. Larger-sized circular cross-section runners are used to reduce flow velocity and shear rate. Due to the properties of PVC material, the runners and cavity have been reinforced.

Cooling system for 90 degree elbow mold

"How can this unique mold mechanism be cooled?"—This is almost always the first and common question we encounter when introducing this design to every client. Because of the segmented design of the core, it's impossible to design an effective cooling system at the core itself. During continuous production, the collapsible core will overheat. We turned our attention to the innovative approach of external cooling gas. Practice is the sole criterion for testing truth: today, this solution has been successfully validated by our clients from South Africa, the United States, and other locations. One of our American partners, after rigorous testing, resolutely decided to invest in building a dedicated cold chamber to maximize the mold's production efficiency and product consistency. Their success powerfully demonstrates the feasibility and immense value of this solution.

Molding cycle of the 90 degree elbow mold

PVC material is prone to overheating and decomposition during injection molding, so the injection speed cannot be too fast; otherwise, shear heat will cause decomposition and charring. This limits the reduction of injection time. The molding cycle of this 90-degree elbow mold is approximately 56 seconds. The video below shows two complete molding cycles. This data is only from the mold testing process. In actual production, the molding cycle will be shorter.

Your Partner in Precision: From DFM to Delivery

As your trusted manufacturer of 90 elbow injection mold systems, we don't just build to print; we partner in your success.

- Proactive Technical Support: Every project begins with a comprehensive DFM (Design for Manufacturability) analysis. We ensure your product is not only design-perfect but also production-ready, optimizing for quality and cost-efficiency.

- Proven Track Record: Wondering how to make a 90 elbow mold that stands the test of time? Look at our portfolio. Explore our successful case studies on Tee fitting molds and 180 degree elbow molds to see our expertise in action.

- Unbeatable Speed to Market: Your time is money. We guarantee a swift 30-day delivery cycle from order confirmation, getting you into production faster.

FAQ