Professional Plastic Pipe Fitting Mould Manufacturer With 20 Years Of Experience - Spark Mould

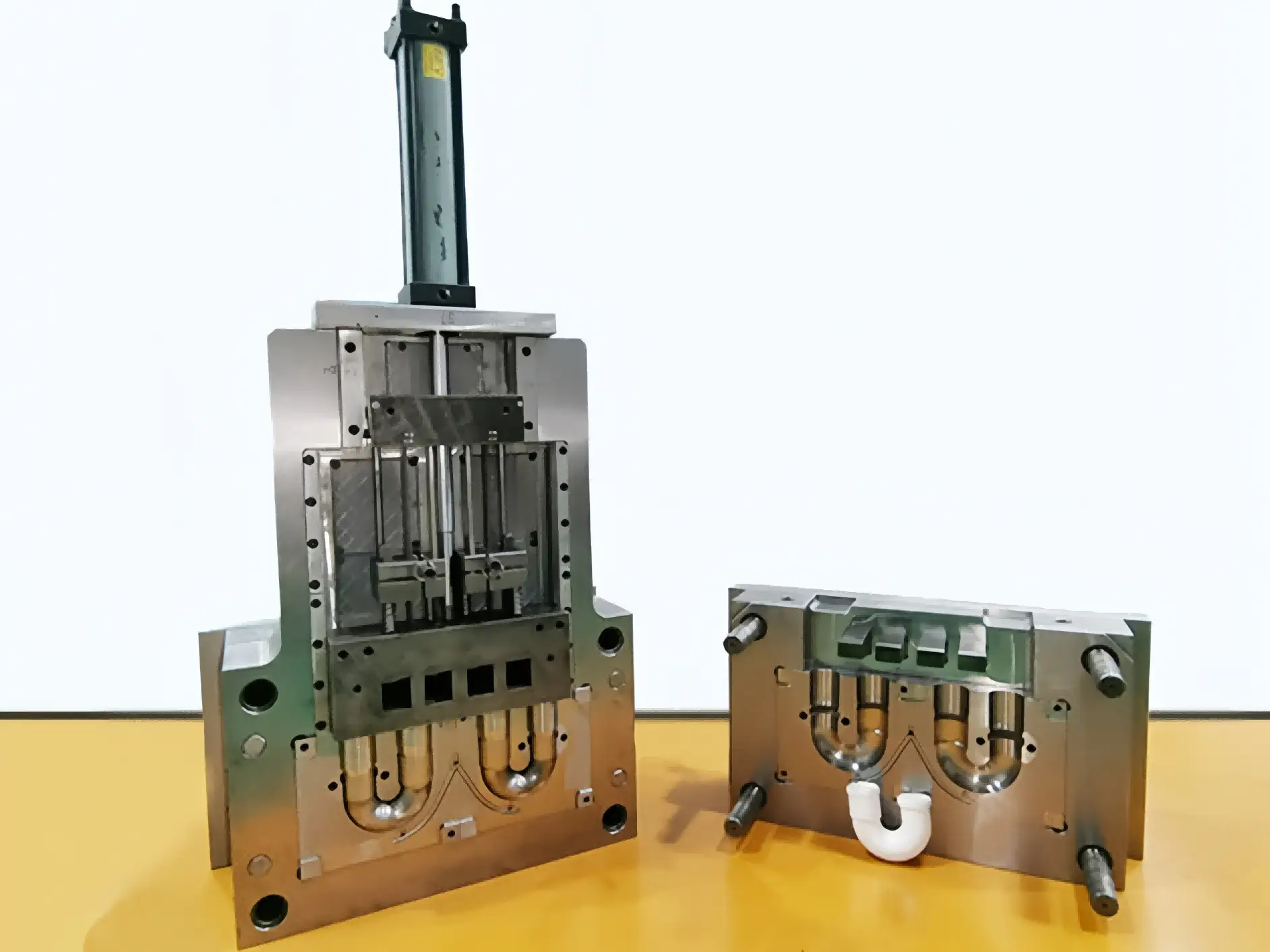

DWV 180 Degree Elbow Injection Mould - Spark Mould

The 180 Degree Elbow Mold is a critical tool for manufacturing pipes and tubing with precise bends. Ideal for creating smooth and even bends in a variety of materials, this mold ensures consistent and accurate results every time. Whether you are producing plumbing fixtures, automotive components, or industrial machinery, the 180 Degree Elbow Mold will help streamline your production process and achieve high-quality finished products.

Innovative Design, Maximum Flexibility

Our 180 Degree Elbow Mold offers precise shaping and high quality construction for seamless pipe connections. The durable design and smooth finish ensure a reliable and leak-free seal, making installation quick and convenient. Available in various sizes, our elbow mold is ideal for a range of plumbing projects.

Product Display

Product Advantage

Efficient Bend Precision Molding

The 180 Degree Elbow Mold features a core attribute of precision engineering, ensuring a perfect fit for seamless pipe connections. Its extended attribute includes durable material construction, guaranteeing longevity and resistance to wear and tear. This product function attribute allows for smooth and efficient fluid flow, essential for plumbing systems.

Application Scenario

FAQ