Professional Plastic Pipe Fitting Mould Manufacturer With 20 Years Of Experience - Spark Mould

Precision Mold for Food Packaging: 0.5mm Chocolate Stick Cup

This project serves as a perfect case study of our expertise in precision mold making. It highlights how we navigate the complex intersection of ultra-thin wall geometries (0.5mm) and the rigorous mechanical requirements of automated assembly. By integrating advanced machining technologies with deep material science insights, we successfully addressed the client’s need for a solution that is both resource-efficient and optimized for the high-velocity demands of the European food market. Let's dive in.

Project Overview: The 0.5mm Challenge

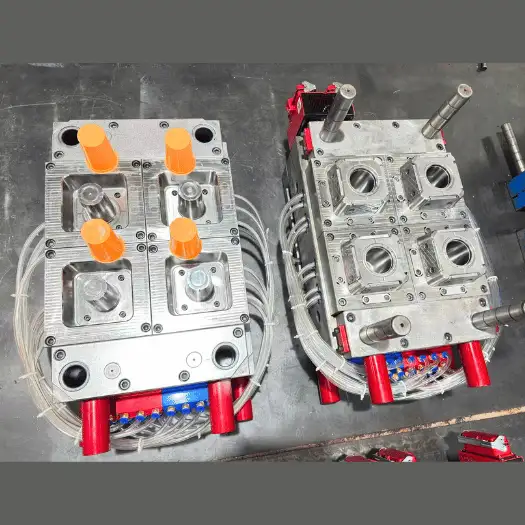

The project consists of two separate components designed to fit perfectly together:

1. 130ml Outer Cup: A 4-cavity mold.

2. Inner Dipping Tray: An 8-cavity mold.

Both components are made from Food-Grade PP, featuring an ultra-thin wall thickness of only 0.5mm. Such a thin-walled design requires not only high-speed injection but also extreme mold stability and precision.

Key Mold Specifications:

| Component | Cavity | Mold Size | Runner System | Cycle Time |

| 130ml Cup | 4 Cavity | 410 x 600 x 585 mm | YUDO Valve Gate | 10 - 12s |

| Dipping Tray | 8 Cavity | 460 x 920 x 549 mm | YUDO Valve Gate | 10 - 12s |

Meeting Automation Requirements: The "Perfect Fit"

Our Czech client emphasized two critical functional requirements for their automated assembly line:

- Secure Locking: The dipping tray must snap into the cup firmly enough to stay in place during filling.

- Natural De-stacking: The cups must drop naturally when stacked, preventing any jams in the automated machine.

To achieve these, we controlled the tolerances within ±0.01mm, ensuring that the interference fit between the two components remains consistent across millions of production cycles.

Technical Breakthroughs: How We Solved the Challenges

Live Demo: Injection molding cycle process.

Watch the precision in motion! We are testing these molds on the TOYO 180T high-speed injection machine.

When dealing with 0.5mm thin-wall components, speed and stability are everything. This video demonstrates:

- Fast Cycle Time: Achieving a consistent 10-12 second cycle.

- Perfect Filling: The synergy between the YUDO valve gate system and the high-speed press ensures zero defects even at peak speeds.

- Engineered for Volume: Every movement is optimized for high-frequency, automated mass production.

Conclusion: Your Partner for Precision Packaging Molds

This Czech project highlights our ability to combine precision mold engineering with the demands of modern food packaging. Whether it is a plastic cup injection mold or a complex multi-component assembly, we provide solutions optimized for automation and high-speed ROI.

Looking for a reliable supplier for your next thin-wall project? Contact our engineering team today for a professional DFM analysis and quote.