Professional Plastic Pipe Fitting Mould Manufacturer With 20 Years Of Experience - Spark Mould

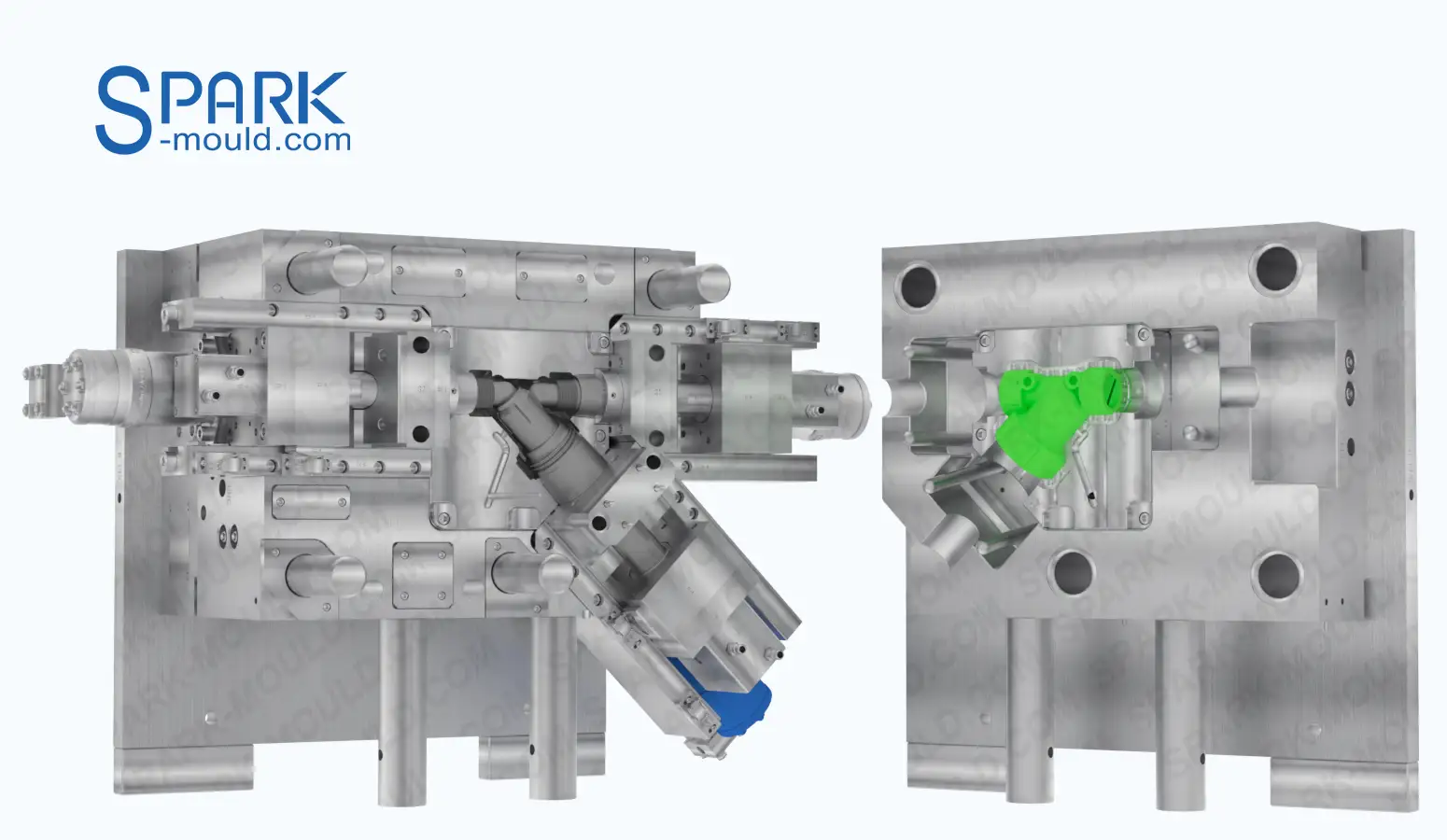

PP thread Wye connector mould - Spark Mould

This is a very complex wys connector mold. Because each port of the connector has a female thread. We designed 3 sets of complex slider assemblies to achieve the molding of the product. When the core pulling mechanism is in operation, it is necessary to loosen the thread first, separate the threaded slider from the product, and then pull out the entire slider assembly.

Wys mold slider assembly

We designed 3 sets of slider assemblies in this wys mold. Each slider assembly has a hydraulic motor and a hydraulic cylinder. The hydraulic motor drives the unscrewing of the threaded slider, while the hydraulic cylinder drives the entire slider assembly to disengage and reset the product. In the figure below, we show the structure of this slider assembly.

Wys mold opening and closing action

When the mold is opened, the inclined guide column on the fixed mold drives the threaded slider seat to move back a certain distance. The hydraulic motor loosens the thread to make the threaded slider separate from the product. Then the hydraulic cylinder drives the entire slider assembly to separate from the product.