Professional Plastic Pipe Fitting Mould Manufacturer With 20 Years Of Experience - Spark Mould

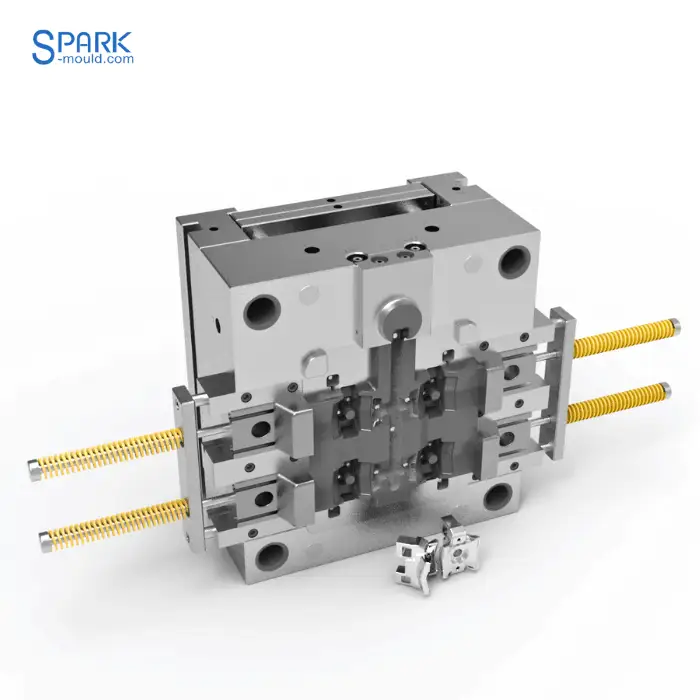

Cold Chamber Die Casting Tooling For Aluminum Alloys Pats

The Critical Role of Die Cast Tooling in Cold Chamber Processes

Cold chamber die casting distinguishes itself by separating the melting furnace from the injection system, requiring tooling to endure abrupt temperature shifts during each cycle. Unlike hot chamber systems, where tooling interacts continuously with molten metal, cold chamber setups demand tooling capable of:

- Resisting Thermal Shock: Aluminum's 660°C melting point requires tooling materials with exceptional thermal stability.

- With standing High Pressures: Typical injection pressures of 400-900 kg/cm² necessitate robust structural design.

- Ensuring Precision Replication: Micro-surface finishes as low as Ra 0.2μm enable complex geometries in automotive and aerospace components.

Modern die cast tooling integrates advanced cooling systems, with conformal cooling channels reducing cycle times by 20-30% while maintaining uniform temperature distribution.

Material Science Breakthroughs for Die Cast Tooling

The evolution of die cast tooling materials has been pivotal in enhancing performance:

| Material Grade | Key Properties | Applications |

| H13 Steel | High toughness, thermal fatigue resistance | General-purpose aluminum casting |

| 8407 Steel | Superior thermal conductivity, wear resistance | High-volume automotive components |

| DAC55 | Exceptional high-temperature strength | Aerospace structural parts |

| DIEVAR | Optimized hardness-toughness balance | Thin-wall mobile device housings |

Manufacturers increasingly adopt vacuum-treated steels with <0.001% sulfur content to minimize micro-porosity, while surface coatings like titanium nitride (TiN) extend tool life by 300-500%.

Design Innovations in Cold Chamber Tooling

Cutting-edge die cast tooling incorporates computational fluid dynamics (CFD) simulations to optimize:

Gating Systems: Tapered runner designs reducing turbulence by 40%

Overflow Channels: Strategically placed to capture contaminated metal

Ejection Mechanisms: Cam-actuated systems preventing part deformation

Selecting the Right Die Cast Tooling Partner

When evaluating die cast tooling suppliers, consider:

- lMaterial certification

- lCNC machining tolerances

- lPrototype validation capabilities

- lPreventive maintenance programs

Leading manufacturers now offer tooling-as-a-service (TaaS) models, providing performance guarantees and lifecycle cost analyses.

Elevate Your Aluminum Die Casting Capabilities

Investing in precision-engineered cold chamber die casting tooling delivers measurable advantages:

- l25% faster cycle times

- l40% reduction in scrap rates

- l50% extended tool life

Let your aluminum alloy die casting project start with a professional-grade mold! Contact our mold engineers today to get a customized solution for your part needs.