Professional Plastic Pipe Fitting Mould Manufacturer With 20 Years Of Experience - Spark Mould

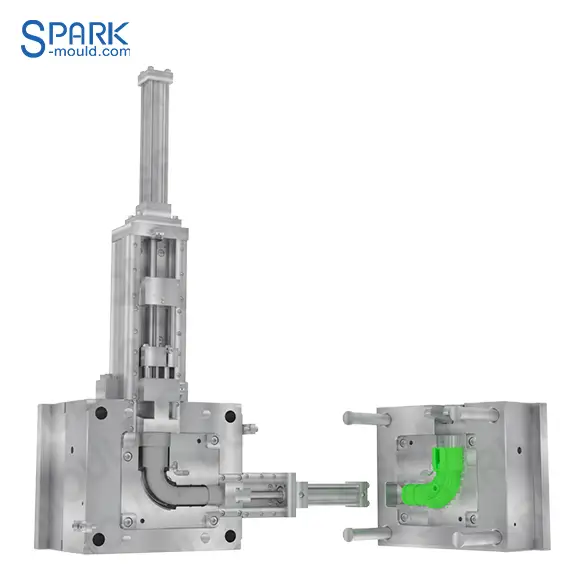

90 degree quick connector injection mold

We have designed a unique collapsible core-pulling mold mechanism for this 90-degree quick connector injection mold. This mechanism is composed of 3 arc-shaped sliders, 2 guide rails, and a wire rope. It is driven by a hydraulic cylinder. The 3 arc-shaped sliders combine the 90-degree core along the guide rail. When the product is ejected, the 3 arc-shaped sliders can separate from each other and move upwards along the guide rail to detach from the product.

Injection Mold Structure

The core of this 90-degree quick connector injection mold is the foldable core mechanism. Its processing and debugging are somewhat difficult. The basic structure of the foldable core is shown in the figure below. The whole mold has two sets of core pulling mechanisms, which are controlled by two hydraulic cylinders respectively.

Hydraulic side core pulling mechanism

Using pressure oil as the power, a special core pulling hydraulic cylinder is configured on the mold, and the piston of the hydraulic cylinder moves back and forth to achieve lateral parting, core pulling and resetting. The action is relatively stable, the pulling force is large, the core pulling distance is long, and the time sequence of core pulling can be freely set according to needs.