Professional Plastic Pipe Fitting Mould Manufacturer With 20 Years Of Experience - Spark Mould

Quality Elbow Mould Manufacturing for Sale

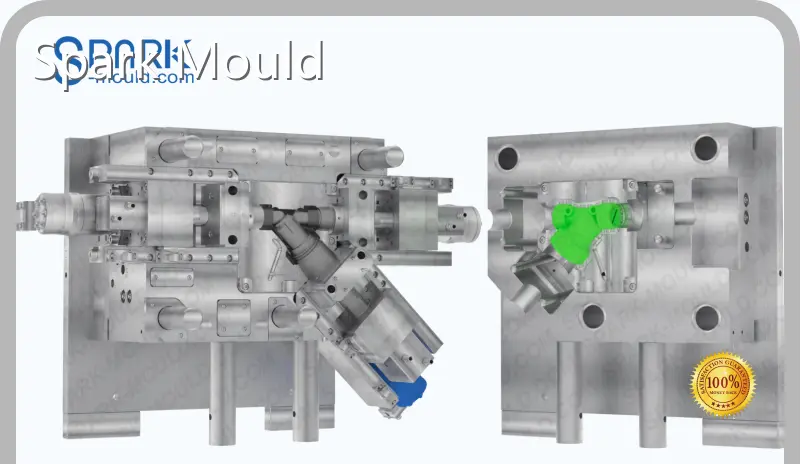

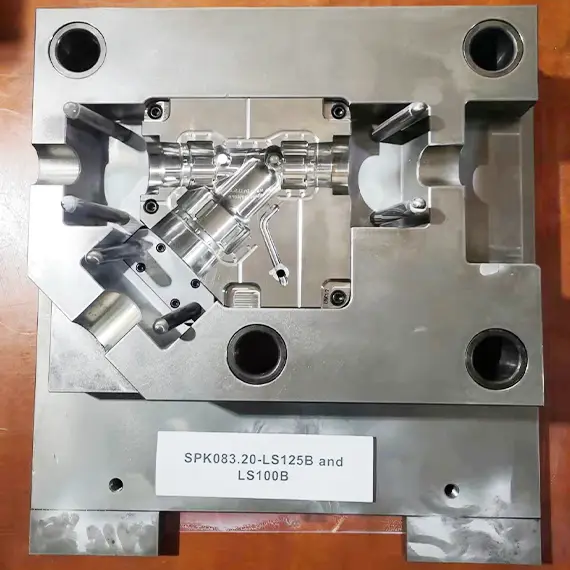

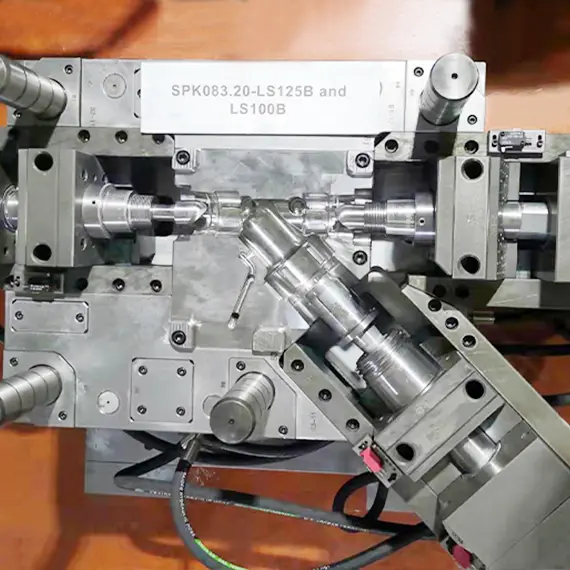

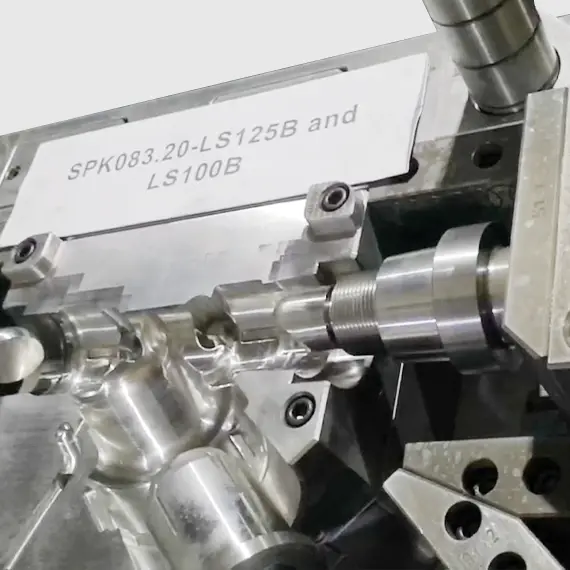

Wys mold slider assembly

We designed 3 sets of slider assemblies in this wys mold. Each slider assembly has a hydraulic motor and a hydraulic cylinder. The hydraulic motor drives the unscrewing of the threaded slider, while the hydraulic cylinder drives the entire slider assembly to disengage and reset the product. In the figure below, we show the structure of this slider assembly.

Wys mold opening and closing action

When the mold is opened, the inclined guide column on the fixed mold drives the threaded slider seat to move back a certain distance. The hydraulic motor loosens the thread to make the threaded slider separate from the product. Then the hydraulic cylinder drives the entire slider assembly to separate from the product.

Mold Trial Video

Company Advantages

· There are different elbow mould in various sizes available.

· With the quality certification, the product is of higher performance than other products.

· It has gained recognition from almost every of our customers.

Company Features

· Spark Mould Technology Co., Ltd. has become one of the preferred manufacturers of elbow mould. We have been working to diversify our product range.

· The technical level for elbow mould comes up to the advanced level in China.

· Spark Mould Technology Co., Ltd. has the strong professional team to solve your all problems. Get more info!

Application of the Product

elbow mould of Spark Mould is widely used and has a wide range of applications.

Our solutions are specially set up to the customer's actual situation and needs to ensure that the solutions provided to the customer are effective.