Professional Plastic Pipe Fitting Mould Manufacturer With 20 Years Of Experience - Spark Mould

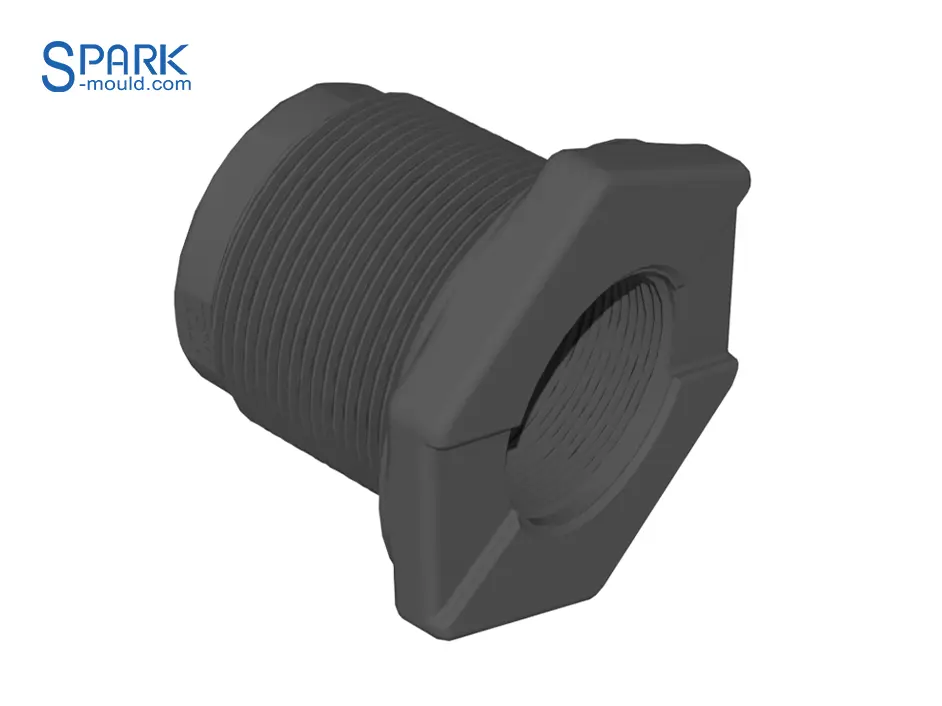

Pvc Pipe Fitting Mold - for Sale - Spark Mould

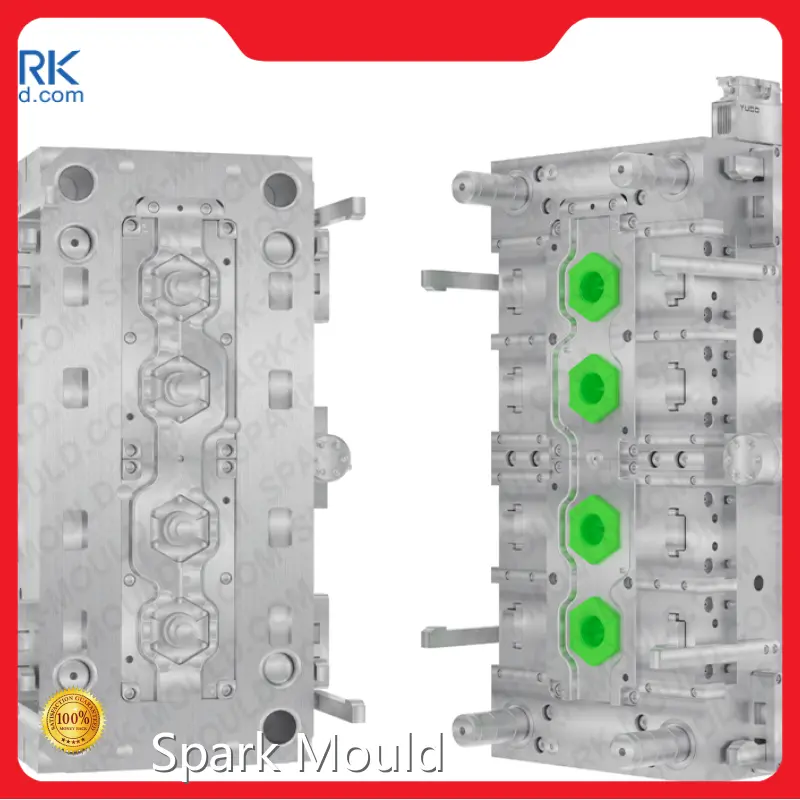

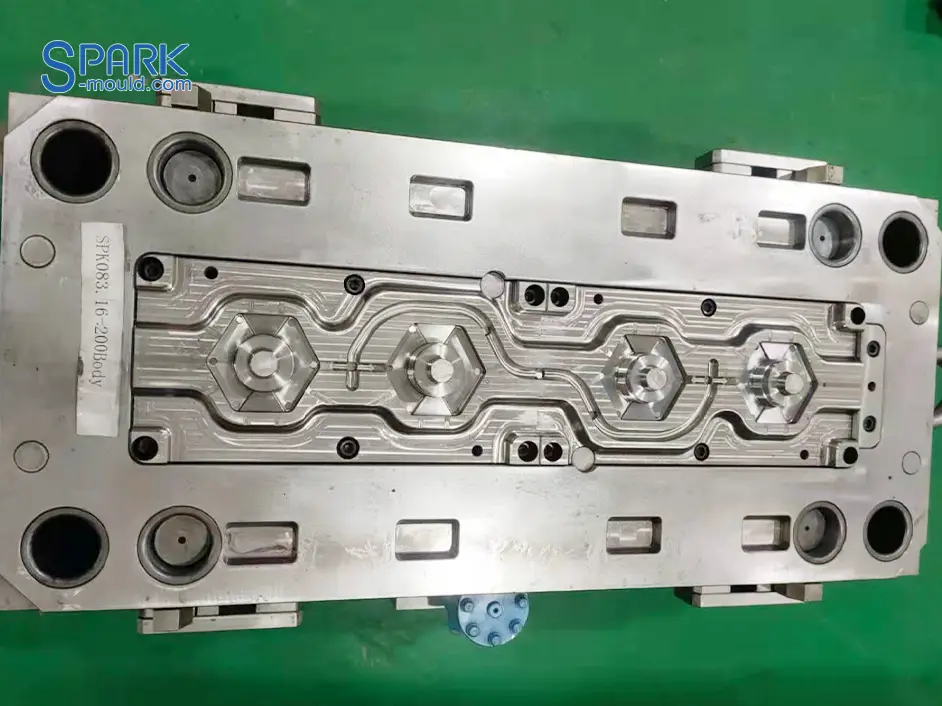

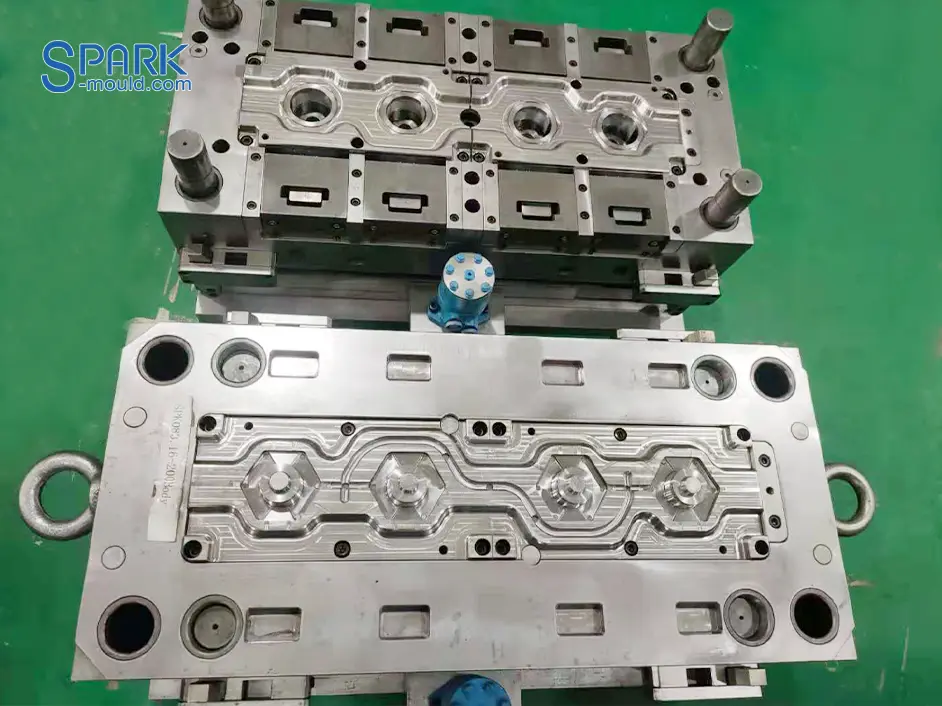

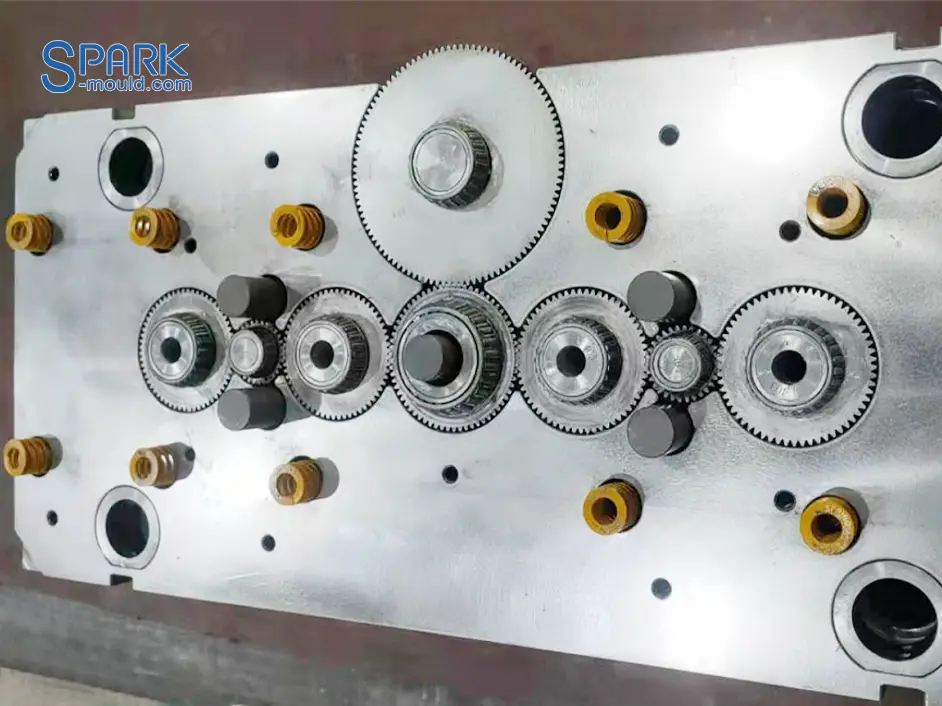

Automatic unscrewing thread mold mechanism

During the injection molding process, the plastic part will be tightly wrapped around the threaded core of the mold after cooling and finalizing. The function of the automatic thread removal mechanism is to separate the threaded core from the plastic part through a specific mechanical movement when the mold is opened. This prevents the plastic part from being difficult to ejection due to the threaded structure, ensuring the continuity of production and the integrity of the product.

Hydraulic cylinders are set on different sides of the movable mold and the fixed mold to drive the unscrewing thread mechanism. Because the mold has 4 cavities, each set of mechanisms consists of 8 sets of gears and bearings.

Mold Trial Video

Company Advantages

· Beautifully designed, Spark Mould pvc pipe fitting mold has been given various attractive styles.

· The product is examined on set industry standards to eradicate all the flaws.

· With the huge application prospect, the product is profoundly preferred by our customers.

Company Features

· Spark Mould Technology Co., Ltd. is one of the most widely recognized manufacturers of pvc pipe fitting mold. We have splendid experience in product fabricating and processing.

· With abundant technical power, Spark Mould is competitive in the pvc pipe fitting mold field.

· We are honest and straightforward. We say what needs to be said and hold ourselves accountable. We earn the trust and confidence of others. Our integrity defines and leads us. Get price!

Application of the Product

Spark Mould's pvc pipe fitting mold is widely used in the industry and is widely recognized by customers.

Spark Mould is committed to producing quality Plastic Pipe Fittings Mold and providing comprehensive and reasonable solutions for customers.