Professional Plastic Pipe Fitting Mould Manufacturer With 20 Years Of Experience - Spark Mould

For Industry Plastic Pipe Fitting Mold by Spark Mould

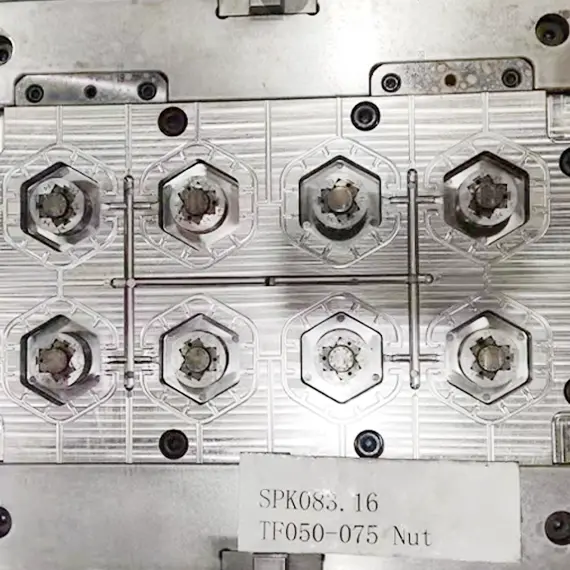

Product details of the plastic pipe fitting mold

Quick Overview

The material used for plastic pipe fitting mold makes its life span longer than others with normal material. plastic pipe fitting mold functions perfectly in the development of the multiple application needs. Our plastic pipe fitting mold has been widely used in many industries. Our professional QC will strictly check all plastic pipe fitting mold before delivery.

Product Information

Compared with similar products in the market, the plastic pipe fitting mold of Spark Mould has the following main advantages.

Collapsible Slider Core Pulling Mechanism

We designed 7 delicate parts to combine the collapsible core. In this innovative design, the retraction and reset mechanism of the slider becomes the core highlight of the entire system. In the key link of product ejection, the core must first complete the contraction under the guidance of the push plate to create the necessary space conditions for the smooth ejection of the product.

Delayed Ejection Mechanism

During the ejection process, the push plate pushes the movable mold forward a certain distance through the push rod, causing the threaded slider to contract, releasing the product, and then the ejector pin ejects the product.

Mold Trial Video

In the video we can clearly see the folding core and the ejection mechanism in action. These are two key factors of this mold.

Company Advantages

Spark Mould Technology Co., Ltd. is always committed to the production, processing and sales of Plastic Pipe Fittings Mold. Our company promises a strong protection in product storage, packaging and logistics and other links. In the after-sales service, we provide professional customer service to answer all kinds of doubts of customers. The product can be replaced at all times once it is confirmed to have quality problems. All customers are sincerely welcomed to contact us for consultation!