Professional Plastic Pipe Fitting Mould Manufacturer With 20 Years Of Experience - Spark Mould

Fitting Mould by Spark Mould

Product details of the fitting mould

Product Overview

Spark Mould Technology Co., Ltd. can offer all sizes of fitting mould. This product is tested on defined parameters to ensure its reliable performance, longer service life, and durability. The product is well-received in the global market and has a great potential of being used more widely in the future.

Product Introduction

Spark Mould's high-quality fitting mould is produced according to the national standards. The specific details are as follows.

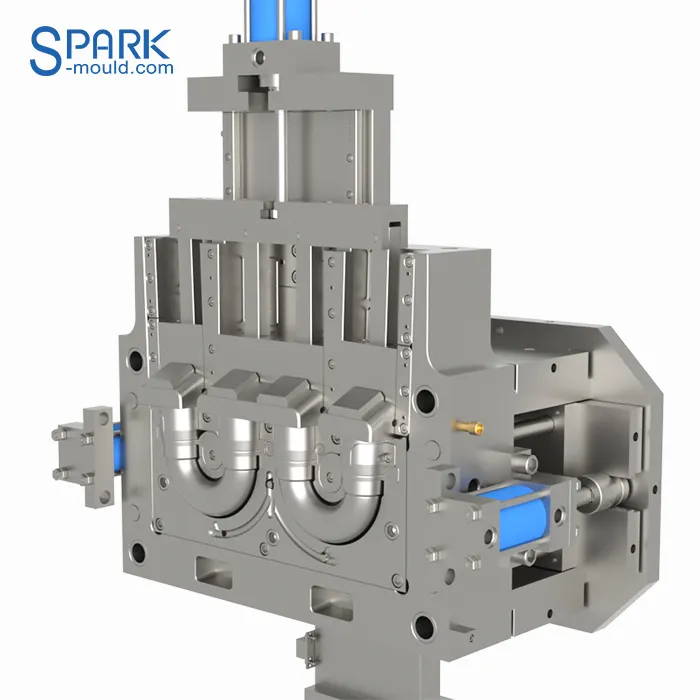

PVC 180 Degree Elbow Mold Structure

The core of this 180 Degree Elbow Mold is the entire mechanism for rotating the product. First of all, in order to eject the product smoothly, the mold core needs to be designed in sections. This 180 Degree Elbow Mold core is divided into 3 sections as shown below:

This elbow mold is designed with a total of 4 hydraulic cylinders to provide power for the 3-step elbow ejection process. Its basic structure is shown in the figure below:

180 Degree Elbow Mold Mechanism Simulation

As shown in the video. The ejection process of this PVC 180 Degree Elbow Mold is divided into 3 steps.

Step 1: The hydraulic cylinder on the upper side of the movable mold pulls out the core block of the elbow

Step 2: The hydraulic cylinders on both sides of the movable mold pull the ejector plate to eject the core, elbow and rotating arm together

Step 3: The hydraulic cylinder on the rear side of the fixed mold drives the linear gear to rotate, and the swing arm rotates accordingly. Then the rotating arm moves the product out and separates it from the mold core.

What Makes Our PVC 180 Degree Elbow Mold Stand Out?

Precision Engineering

Our return bend molds are crafted with cutting-edge CNC machining technology, ensuring exact dimensions and smooth finishes for PVC 180 degree elbows. This eliminates leaks and guarantees seamless integration into DWV systems.

Durability & Longevity

Constructed from high-grade steel with advanced heat treatment, our pvc 180 degree elbow molds withstand high-pressure injection cycles, reducing downtime and maintenance costs.

Versatile Design

Compatible with all standard PVC materials, our molds produce return elbows that meet ASTM, ISO, and NSF certifications, ideal for plumbing, HVAC, and industrial applications.

Cost-Efficiency

Optimized cooling systems and multi-cavity options maximize production output, lowering per-unit costs for high-volume orders.

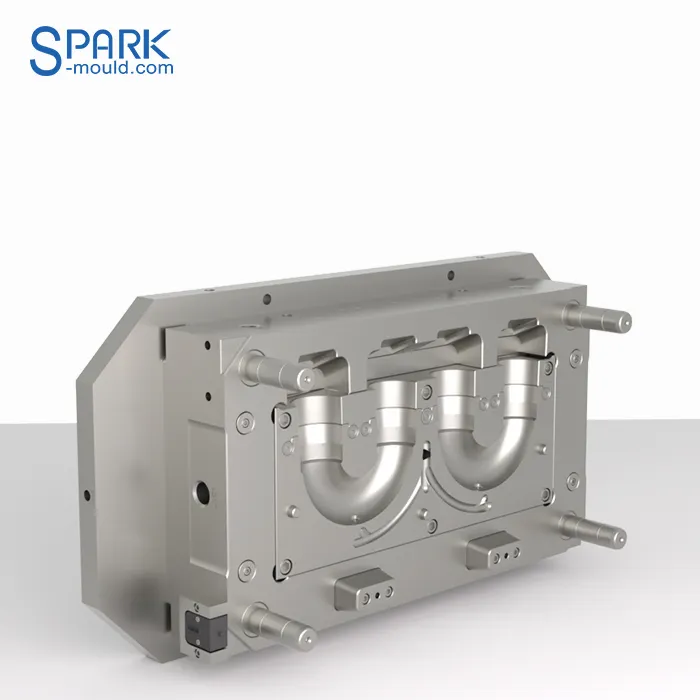

DWV PVC 180 Degree Return Elbow

The core value of the DWV PVC 180-degree return elbow lies in its U-shaped structural design, which can accurately achieve a 180-degree reversal of the pipe direction. This feature allows it to store a certain amount of liquid in the pipe, prevent sewer gas backflow, and ensure indoor air quality. In basements, equipment mezzanines or narrow pipe shafts, return elbows can replace multiple short-radius elbows, reduce connection points, and reduce the risk of leakage.

PVC 180 Degree Elbow Cross-industry Applications

Residential Construction: Perfect for sewage lines, basement drainage, and kitchen/bathroom plumbing.

Commercial Projects: Supports large-scale HVAC systems and waste management in malls, offices, and hospitals.

Agricultural Use: Durable return elbows for irrigation channels and livestock water systems.

Upgrade your production line with our industry-leading PVC 180 degree elbow mold! Contact us today for a quote, and let us help you dominate the return bend market with precision-engineered solutions.

Company Introduction

Today, Spark Mould Technology Co., Ltd. has become one of the best manufacturers majoring in the development, design, and production of fitting mould. We have a large manufacturing facility that is well equipped. It has an extensive list of manufacturing equipment, allowing us to be a qualified manufacturing partner. We stick to sustainable development. We ensure proper sustainable management by reducing wastes generated and reuse materials as possible.

Do not hesitate to contact us if you are interested in ourPlastic Pipe Fittings Mold.