Professional Plastic Pipe Fitting Mould Manufacturer With 20 Years Of Experience - Spark Mould

Factory Price Fitting Mould Price List

Product details of the fitting mould

Product Introduction

The fact that putting investment into the design of fitting mouldis icing on the cake for the popularity of Spark Mould. The product is quality assured as it has undergone numerous rigorous tests before coming into the market. Spark Mould has enough storage capacity to offer mass production of fitting mould.

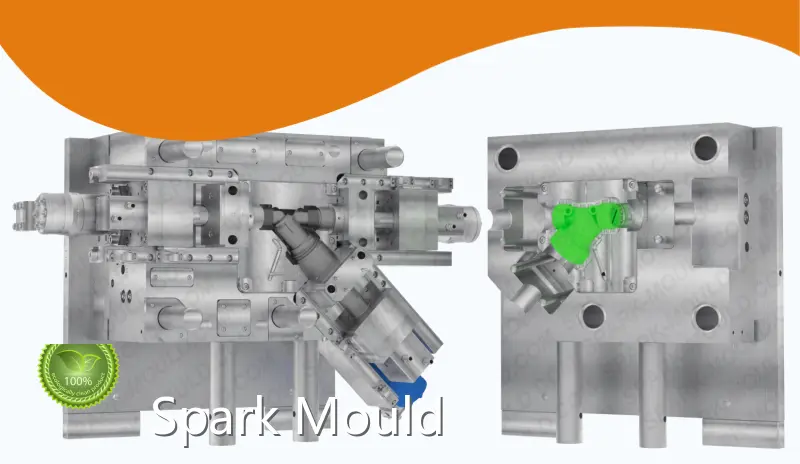

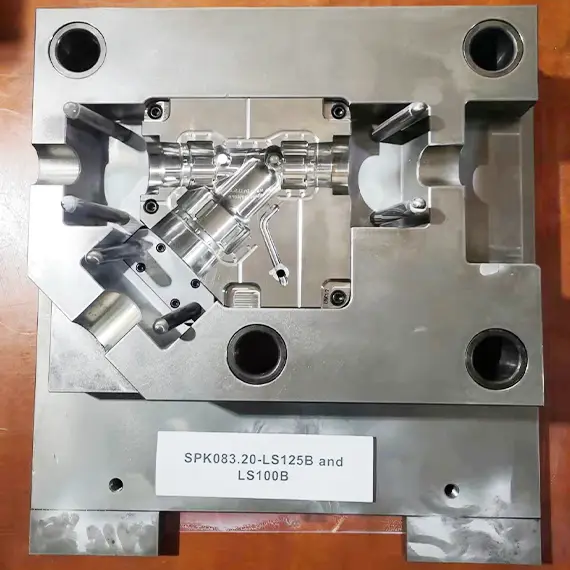

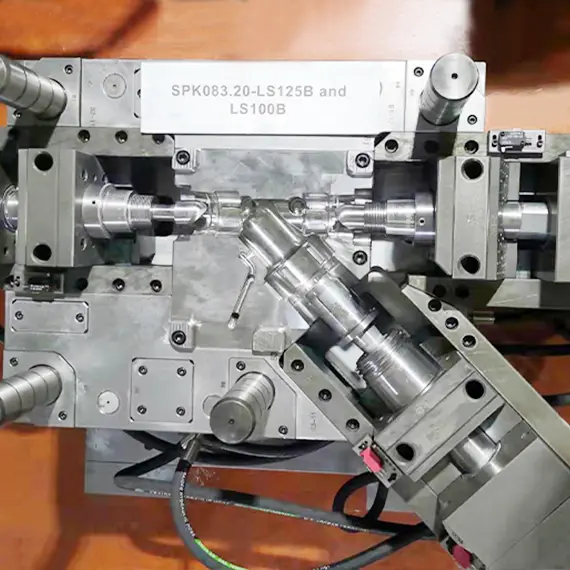

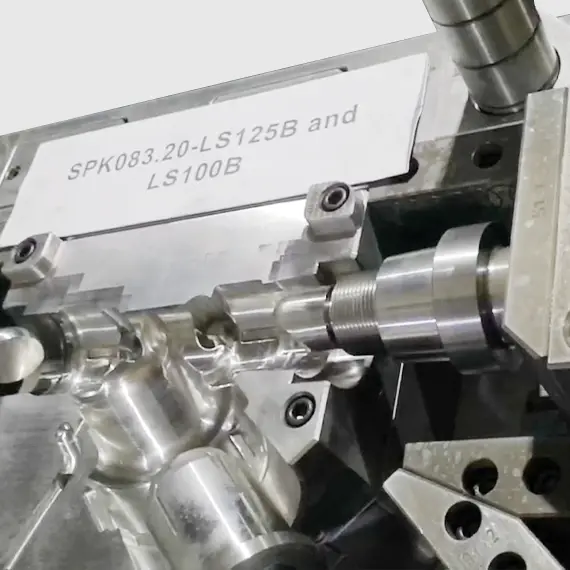

Wys mold slider assembly

We designed 3 sets of slider assemblies in this wys mold. Each slider assembly has a hydraulic motor and a hydraulic cylinder. The hydraulic motor drives the unscrewing of the threaded slider, while the hydraulic cylinder drives the entire slider assembly to disengage and reset the product. In the figure below, we show the structure of this slider assembly.

Wys mold opening and closing action

When the mold is opened, the inclined guide column on the fixed mold drives the threaded slider seat to move back a certain distance. The hydraulic motor loosens the thread to make the threaded slider separate from the product. Then the hydraulic cylinder drives the entire slider assembly to separate from the product.

Mold Trial Video

Company Feature

• Spark Mould has a management team and a staff team, who are both young, market-oriented and knowledgeable. The team members are equipped with strong team spirit and innovative consciousness. All of us strive to produce quality products with common efforts.

• Since the establishment, our sales network has been continuously expanding to where our sales service is highly appraised by customers at home and abroad. In future, we would like to establish our marketing network overseas and expand the business further.

• Based on customer demand, Spark Mould is committed to providing considerate services for customers.

Spark Mould's Plastic Pipe Fittings Mold are all qualified by national certification. If you have any needs, please contact us as soon as possible.