Professional Plastic Pipe Fitting Mould Manufacturer With 20 Years Of Experience - Spark Mould

Elbow Mould Pipe Elbow Mould Wholesale - Spark Mould

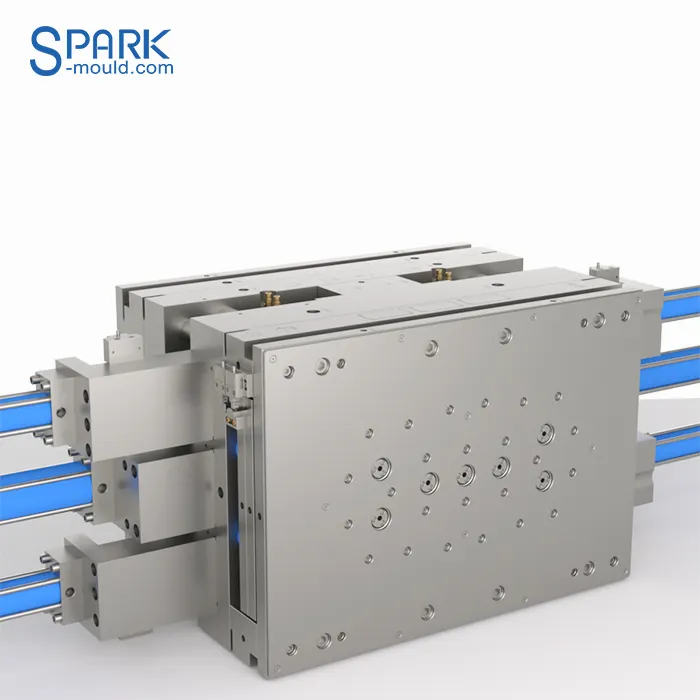

Product details of the elbow mould

Product Information

Each raw material of Spark Mould elbow mould is carefully selected. According to the acquirement of customers, our technicians have successfully improved elbow mould. The product becomes very popular with its marked features among customers in the industry.

J Bend P Trap Mold Structure

The core of this j bend p trap mold is the core pulling action of the j bend arc segment. Its core is composed of a 1-to-2 Crank-Slider Mechanism. This special four-bar linkage mechanism drives the mold core to rotate through the extension and retraction of the hydraulic cylinder.

We designed a two-step separation for the core part of this J Bend P Trap mold. Because rotating the core 90 degrees is not enough to completely separate from the product. If the angle is increased, the core and the product will interfere with each other. Therefore, we designed two fixed points on the crank part. When the core rotates 90 degrees, the first fixed point is released. The crank rotates around the second fixed point, one end of the core will rise, and then separate from the product.

J Bend P Trap Mold Dynamic Simulation

As shown in the video. This J Bend P Trap Mold Crank-Slider Mechanism has 3 steps in total.

Step 1: The hydraulic cylinder first pulls the slider up a certain distance and pulls out the slider of the J Bend port;

Step 2: The rising slider is locked, driving the pull rod to rise. The pull rod pushes the slider groups on both sides to rotate 90 degrees;

Step 3: The first fixed point is released, and the pull rod continues to push the crank to rotate. The product is completely separated from the core.

4-Cavity PVC P Trap Molds: Efficiency Meets Precision

A 4-cavity P Trap mold is designed to maximize production efficiency by molding four units per cycle. This multi-cavity approach reduces manufacturing costs and cycle times, making it ideal for large-scale orders. Here’s what sets high-performance P Trap molds apart:

1. Advanced Mold Design

Flow Analysis: Optimized runner and gate systems ensure even material distribution across all cavities, minimizing defects like air pockets or warping.

Cooling Channels: Strategically placed cooling lines reduce cycle times by accelerating solidification of PVC.

Durable Steel Construction: Heat-treated tool steels (e.g., H13 or S136) enhance mold longevity, even under high-pressure injection molding conditions.

2. Consistency & Quality Control

4-cavity molds ensure uniform wall thickness and dimensional accuracy across all units, critical for leak-proof performance. Automated ejection systems further streamline production while protecting delicate J Bend structures.

3. Cost-Effective Scalability

By quadrupling output per cycle, manufacturers achieve faster ROI while maintaining tight tolerances (±0.02mm). This scalability is vital for meeting global demand for PVC sink traps.

Sink Plumbing Knowledge: Why P Trap Molds Matter in Sink Plumbing Systems

The sink trap (commonly a J Bend P Trap) is a U-shaped pipe under sinks that retains a small amount of water to block toxic gases and odors. Made from corrosion-resistant PVC, these traps are lightweight, affordable, and easy to install.

Key features of an effective J Bend P Trap include:

Smooth internal walls to prevent clogs.

Accurate bend angles for optimal water sealing.

Durable PVC material resistant to chemicals and temperature fluctuations.

Upgrade Your Production Line Today

Whether you are producing J-elbows, U-elbows or other P-trap systems, we can provide reasonable mold solutions for your products. Partner with a mold specialist to optimize your sink plumbing components and stay ahead in the competitive sanitaryware market.

Company Advantage

• The superior location and traffic convenience lay a good foundation for Spark Mould's development.

• Spark Mould has an experienced service team and a complete service system to provide quality and considerate services for customers.

• We have been dedicated to the manufacturing of Plastic Pipe Fittings Mold for about years, and have become the leading enterprise in the industry. This enables us to introduce and operate a complete set of production equipment, and achieve intelligentization and standardization.

• Since the establishment, our sales network has been continuously expanding to where our sales service is highly appraised by customers at home and abroad. In future, we would like to establish our marketing network overseas and expand the business further.

We look forward to working with you to move towards a more brilliant era.