Professional Plastic Pipe Fitting Mould Manufacturer With 20 Years Of Experience - Spark Mould

Plastic Cap Moulds: The Role in Packaging Industry Evolution

In the ever-evolving landscape of the packaging industry, one component stands out as pivotal: plastic cap moulds. These essential tools have transformed how we package and protect various products, driving innovation and sustainability. Imagine a world where every bottle, jar, and container is sealed with precision and eco-friendliness. That vision is not just a dream; it is increasingly becoming a reality through advancements in plastic cap mould technology.

Understanding Plastic Cap Moulds and Their Manufacturing Process

What Are Plastic Cap Moulds and How Do They Function?

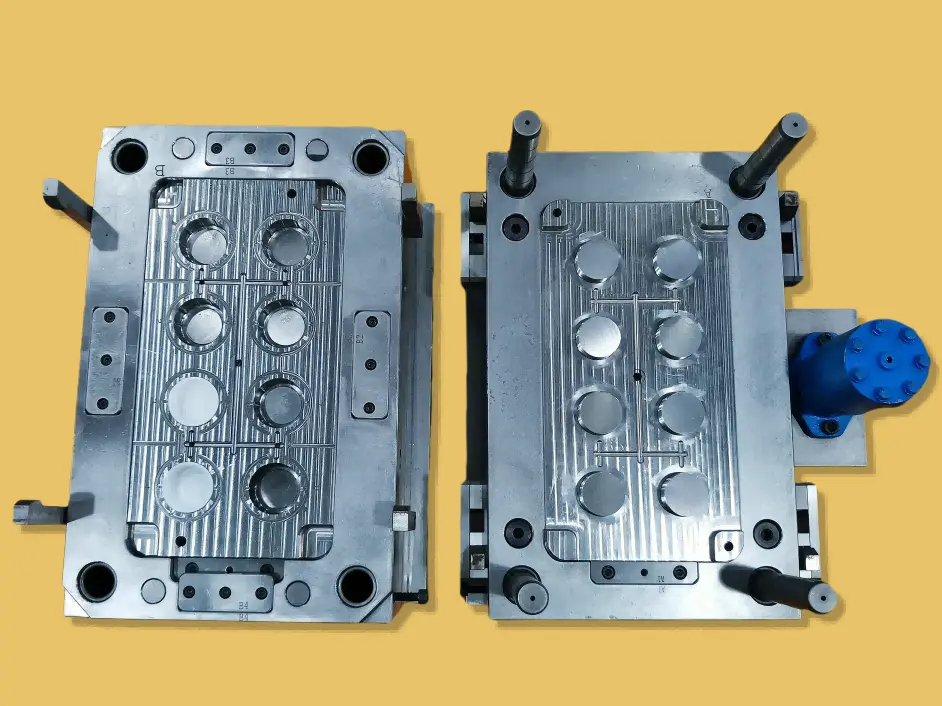

Plastic cap moulds are crucial in the packaging industry, used to create closures for a wide range of products, from food and beverages to household items and cosmetics. The process begins with selecting high-quality thermoplastic polymers, which are melted and then injected into moulds. These moulds imprint plastic caps onto product containers, ensuring a secure and airtight seal.

The manufacturing process involves precise engineering to guarantee that each cap is perfectly formed, durable, and visually appealing. The choice of materials is critical, as they must meet stringent standards for durability and environmental sustainability. This level of precision ensures that the caps protect product integrity and enhance visual appeal, making them an indispensable part of modern packaging.

The Significance of Plastic Cap Moulds in Packaging

Advantages of Using Plastic Cap Moulds in Packaging

Using plastic cap moulds offers several advantages over traditional packaging methods. The first and foremost benefit is the versatility of plastic closures. They can be customized to fit a wide range of products, offering both aesthetic appeal and functional protection. This flexibility allows manufacturers to choose the most suitable cap for their specific product needs.

Another significant advantage is the environmental impact reduction. By using biodegradable and recyclable materials, plastic cap moulds contribute to a greener packaging industry. This shift towards sustainable materials is crucial for meeting consumer demand for eco-friendly products. A report by Grand View Research indicates that the global biodegradable plastics market size is expected to reach $8.8 billion by 2027, underscoring the growing importance of sustainability in packaging.

Innovative Applications of Plastic Cap Moulds in Modern Packaging

Innovative Applications of Plastic Cap Moulds

The packaging industry is continually innovating, and plastic cap moulds are at the forefront of this evolution. Recent advancements in mould technology have led to the creation of highly innovative packaging solutions. For example, personalized caps that can be embossed with product details enhance customer experience and brand loyalty. Another notable development is the use of smart caps, equipped with built-in security features and data tracking capabilities. These smart caps not only enhance security but also provide valuable insights into product circulation and consumption patterns.

The introduction of digital inks and reflective materials further adds a modern touch to traditional packaging. A McKinsey & Company study highlights that the use of smart packaging can increase brand engagement by up to 20%. This transformation not only enhances security but also provides a more engaging and user-friendly experience for consumers.

Future Trends and Challenges in the Packaging Industry with Plastic Cap Moulds

Future Trends and Challenges

As the packaging industry continues to evolve, plastic cap moulds will play a crucial role in shaping the future. Regulatory changes, such as stricter environmental standards, will drive the development of new technologies. At the same time, consumer demand for transparency and traceability will influence how companies use plastic cap moulds.

One of the key challenges is balancing sustainability with cost-effectiveness. Companies must ensure that new technologies meet both environmental and economic requirements. Moreover, meeting consumer expectations for innovative and eco-friendly packaging will be crucial for success in the industry. However, the collaborative spirit and focus on innovation within the industry provide a strong foundation for overcoming these hurdles.

Real-World Examples

Real-World Examples

To illustrate the impact of plastic cap moulds, consider the case of a leading beverage company that redesigned its cap with biodegradable materials. This transformation not only reduced waste but also improved customer perceptions of the brand’s commitment to sustainability. Another example is a consumer goods company that introduced smart caps with built-in security features, enhancing product integrity and consumer trust. These real-world examples demonstrate the practical benefits of using plastic cap moulds in modern packaging.

The Irreplaceable Role of Plastic Cap Moulds

In conclusion, plastic cap moulds are an irreplaceable force in the packaging industry. They drive innovation, enhance sustainability, and improve product protection, making them a cornerstone of modern packaging solutions. As the industry continues to evolve, plastic cap moulds will remain at the forefront, enabling companies to meet the demands of a changing market landscape. By embracing new technologies and sustainable practices, the industry can ensure its continued growth and success.

Companies are encouraged to explore innovative uses of plastic cap moulds to stay ahead in the competitive market. Embrace the future of packaging with plastic cap moulds that not only protect but also promote sustainability and customer engagement.