Professional Plastic Pipe Fitting Mould Manufacturer With 20 Years Of Experience - Spark Mould

Common Cap Mould Types Explained

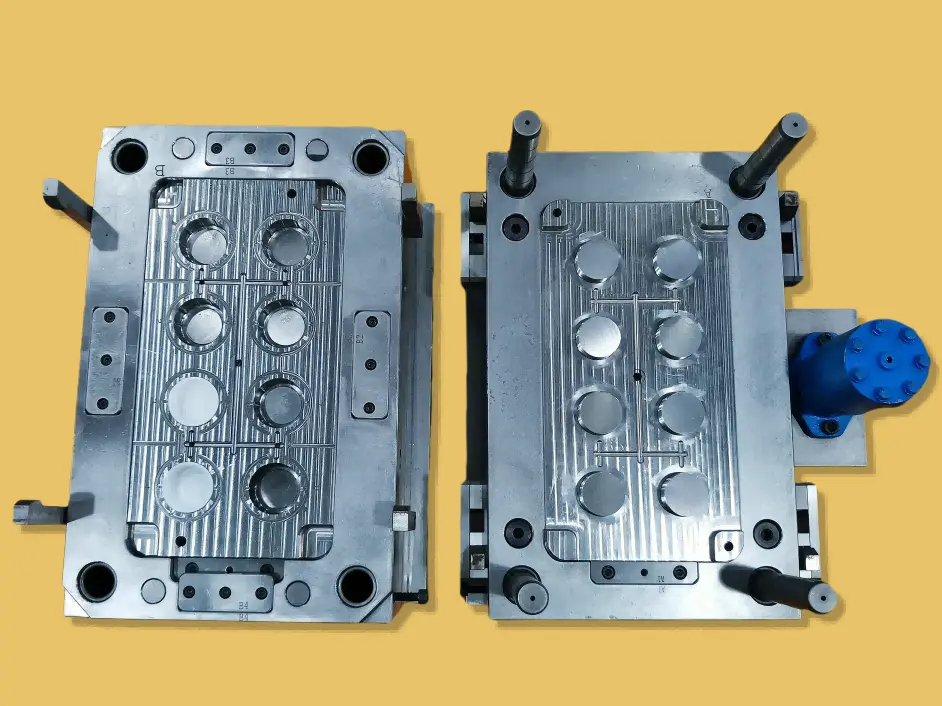

What Are Cap Moulds and How Do They Work?

Cap moulds are specialized tools used to create closures with high precision and repeatability. They work by injecting molten resin into a cavity, where it cools and solidifies to form the closure. This process is essential for ensuring that the final product is both functional and durable.

- Mold Cavity: This part of the mould shapes the closure. It is carefully designed to match the exact specifications of the final product.

- Runner System: Ensures that the molten resin flows evenly into the mold cavity during the injection process.

- Packing: A crucial element that ensures the molten resin is distributed uniformly, preventing air entrapment and creating a consistent fill.

The process begins by heating the resin to its molten state, which is then injected into the mold cavity under high pressure. As the resin cools and solidifies, the closure is formed. The resulting closure is then ejected from the mould, ready for further processing or use.

Ensuring a tight seal between bottle and cap enhances safety and functionality, making cap moulds an indispensable part of modern manufacturing.

Basic Types of Cap Moulds: Injection Moulds vs Blow Moulds

Cap moulds come in two main types: injection moulds and blow moulds. Each type offers unique strengths and is suited to different applications.

- Injection Moulds: Highly versatile and widely used for closures with intricate designs. Injection moulding involves extruding molten resin into the mold cavity, which is then cooled to form the closure. This process is known for its efficiency and ability to produce closures with high precision. Ideal for producing closures such as household bottle caps with detailed designs.

- Blow Moulds: Used for closures with simpler geometries. The blow moulding process involves inflating a hollow die with molten resin, which then flows into the mold cavity. The resulting closure is lightweight and has a uniform thickness. This process is suitable for producing caps for packaging materials such as plastics and rubber. Ideal for lightweight packaging materials.

Understanding the differences between these two types is crucial for selecting the right cap mould for your specific needs.

Advanced Cap Moulds: Electroforming and Composite Moulding

Recent technological advancements have led to the development of more sophisticated cap moulds, such as electroforming and composite moulding.

- Electroforming: Uses electricity to shape molten metal or plastic into the desired closure. This process allows for the creation of closures with complex geometries and high surface finishes. Electroforming is particularly useful for producing closures that require high precision and a smooth finish, such as medical device closures.

- Composite Moulding: Involves using multiple materials within a single mould to create closures with enhanced properties. Composite moulds can improve thermal resistance, impact resistance, and durability. This technology is especially beneficial for high-value products such as automotive parts. Ideal for producing closures with improved thermal and impact resistance.

Both electroforming and composite moulding offer significant advantages over traditional methods, making them valuable additions to the modern manufacturing toolkit.

Design Considerations for Cap Moulds

The design of a cap mould is critical to achieving high-quality closures. Several factors must be considered when designing a cap mould, including the size and shape of the mold cavity, the type of material used, and the packing system.

- Size and Shape: The mold cavity must be designed to accommodate the specific requirements of the closure. This includes the height, width, and depth of the cap.

- Material Selection: The material of the mold cavity is typically made of high-temperature-resistant polymers or metals. These materials can withstand the heat generated during the injection or blow moulding process.

- Packing: The packing system must be carefully designed to prevent air entrapment and ensure a consistent fill of the mold. Proper packing is essential for achieving a uniform closure and preventing warping or cracking during the cooling process.

Proper design and construction are essential for creating closures that are both functional and aesthetically pleasing.

Manufacturing Processes and Their Impact on Cap Moulds

The manufacturing process of cap moulds is a critical factor in determining their quality and performance. Both injection and blow moulding processes are highly controlled and require precise monitoring to ensure the production of high-quality closures.

- Injection Moulding: During the injection moulding process, molten resin is extruded into the mold cavity at high pressure, ensuring a uniform fill. This process is highly efficient and allows for the production of closures with high precision. Ensures a consistent and precise fill, reducing potential defects.

- Blow Moulding: In the blow moulding process, a hollow die is inflated with molten resin, which then flows into the mold cavity. The resulting closure is lightweight and has a uniform thickness. This process is less complex but still produces closures with acceptable levels of quality and functionality. Ensures a lightweight and uniform closure.

The quality of the cap mould itself is also a key factor in determining the outcome of the manufacturing process. Caps with poor design or inadequate cooling systems may produce closures that are prone to warping or cracking. Ensuring a well-designed and well-constructed cap mould is essential for producing high-quality closures.

Real-World Applications of Cap Moulds

Cap moulds are used in a wide range of industries, from packaging and consumer goods to automotive and aerospace. Here are a few examples of how cap moulds are utilized in real-world applications:

- Beverage Industry: A leading beverage company has improved bottle cap quality by implementing advanced cap moulding technology. This technology ensures a tight seal between bottle and cap, reducing waste and production time.

- Pharmaceutical Packaging: A company specializing in pharmaceutical packaging produced closures using composite moulding that can withstand extreme temperatures. These closures are designed to ensure the integrity of the medication during storage and transport.

These case studies highlight the importance of cap moulds in achieving high-quality closures for various applications.

Comparative Analysis: Choosing the Right Cap Mould Type

When selecting a cap mould, it is essential to consider the specific requirements of the closure being produced. Here’s a quick guide on choosing the right type of cap mould:

- Injection Moulds: Ideal for producing closures with intricate designs. This type of mould is suitable for a wide range of products, from household bottles to medical equipment.

- Blow Moulds: Suitable for producing closures with simpler geometries. They are often used for lightweight applications such as plastic and rubber packaging.

- Advanced Cap Moulds (Electroforming and Composite Moulding): These offer enhanced performance but require more specialized equipment and expertise. The choice of cap mould depends on factors such as the complexity of the design, the desired properties of the closure, and the budget available for production.

A comparative analysis of different types can help manufacturers make informed decisions about which technology to adopt for their specific needs.

Future Trends in Cap Mould Technology

The future of cap mould technology is poised for significant advancements, driven by innovations in materials science, automation, and sustainability. Here are a few emerging trends:

- Additive Manufacturing: This technology allows for the production of customised cap moulds, enabling the creation of closures with complex geometries and tailored properties. Additive manufacturing ensures precise and functional closures, meeting the needs of modern manufacturers.

- Automation and Robotics: The integration of automation and robotics is expected to increase, leading to higher levels of precision and consistency. Automation and robotics enhance efficiency and reduce human error.

- Sustainability: Many companies are exploring the use of recycled materials in cap moulds to reduce their environmental impact. Sustainable practices ensure that manufacturers can meet the demands of eco-conscious consumers.

These trends are shaping the future of cap mould technology and are expected to drive innovation and efficiency in the manufacturing industry.

The Role of Cap Moulds in Modern Manufacturing

Cap moulds are the unsung heroes of modern manufacturing, ensuring the production of high-quality closures that meet the needs of today's demanding markets. From injection moulds to blow moulds, and from electroforming to composite moulding, cap moulds offer a wide range of options to meet the diverse needs of manufacturers. The design and manufacturing processes of cap moulds are influenced by factors such as the complexity of the closure, the desired properties of the material, and the budget available for production. As technology continues to evolve, so too will the capabilities of cap moulds, ensuring even higher standards of quality and efficiency in manufacturing.

By understanding the different types of cap moulds and their applications, manufacturers can make informed decisions about which technology to adopt, ultimately leading to improved quality and productivity in their operations.