20+ Years Of Injection Mold Manufacturer

Excellent Service & Rich Experience

What can you get from our mold manufacturing services?

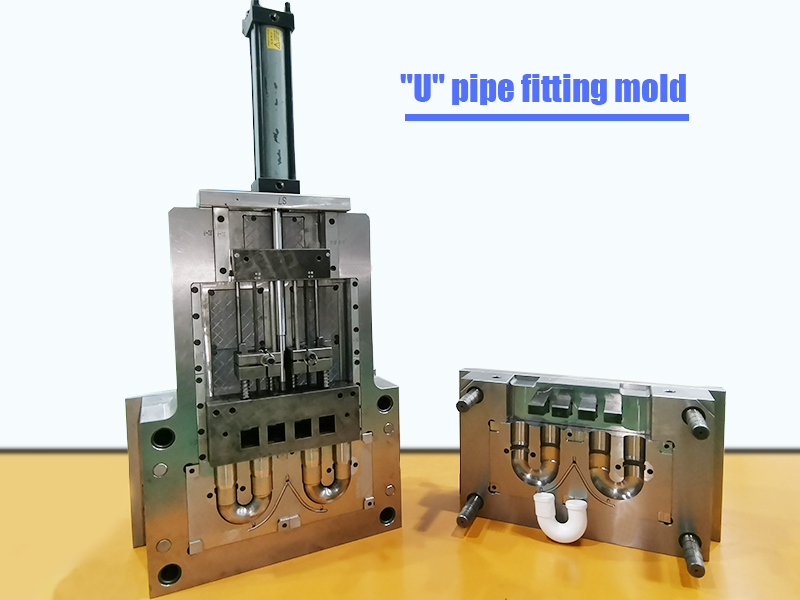

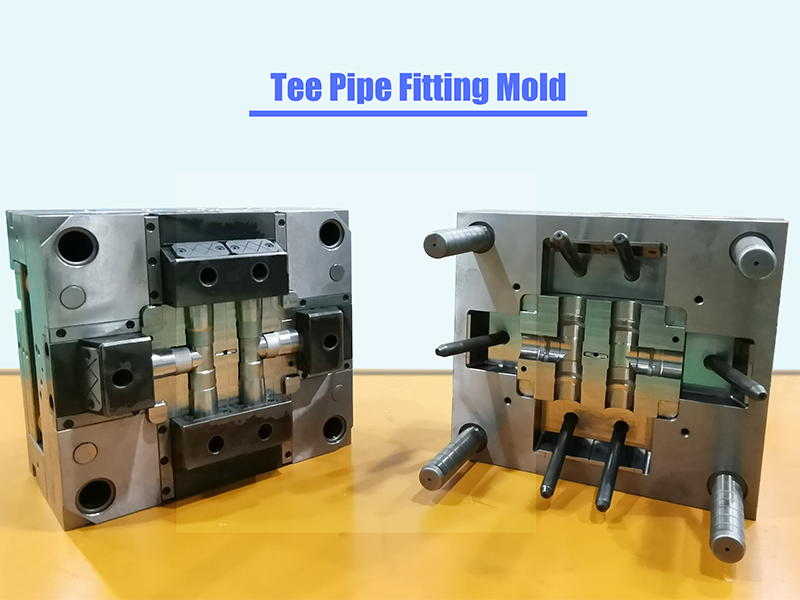

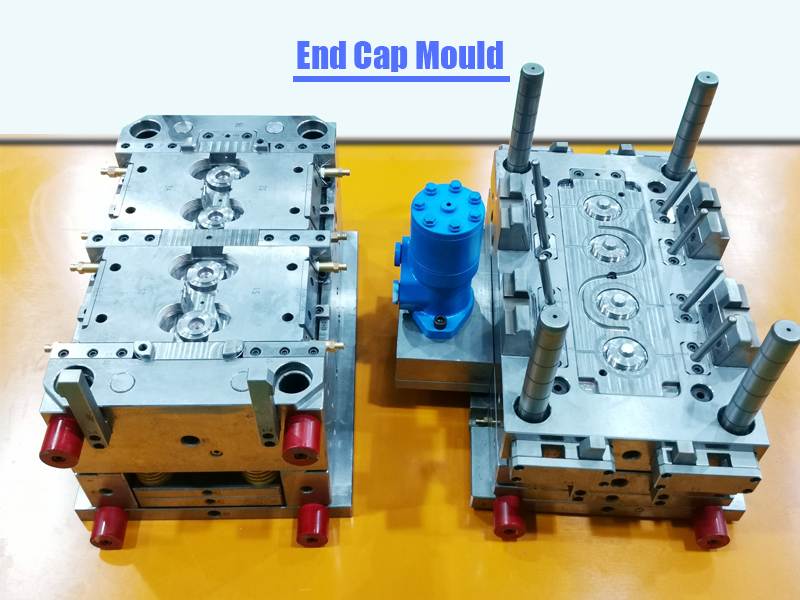

1. Durable and reliable injection mold.

2. 100% tool ownership.

3. Prototype manufacturing.

4. Guaranteed after-sales service.

5. Timely feedback on project progress.

6. Project evaluation and professional advice.

7. Delivery within the specified time.

8. Most competitive prices in the market

Tolerance:

Min 0.01mm

Maximum Weight:

20 tons

Maximum Size:

1.5m×2m

Annual Output:

400 +sets

Delivery Time:

3-10 weeks

Mold Life:

1000000+ shots

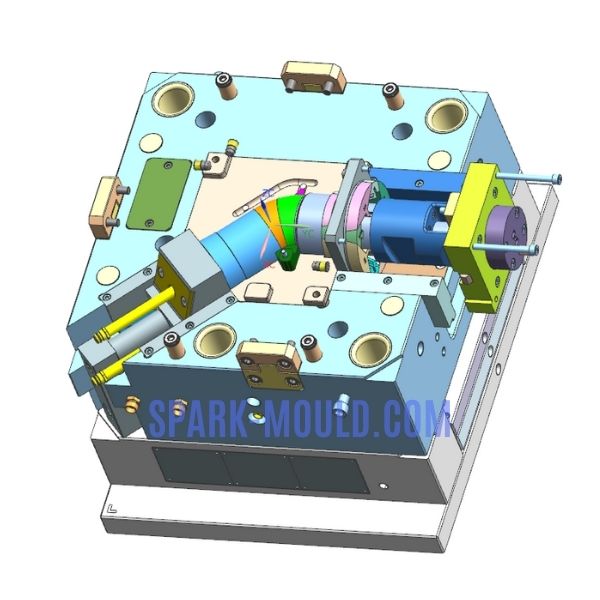

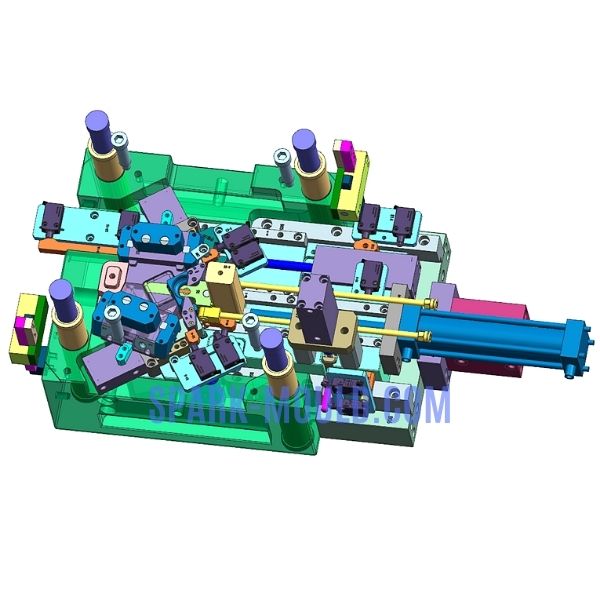

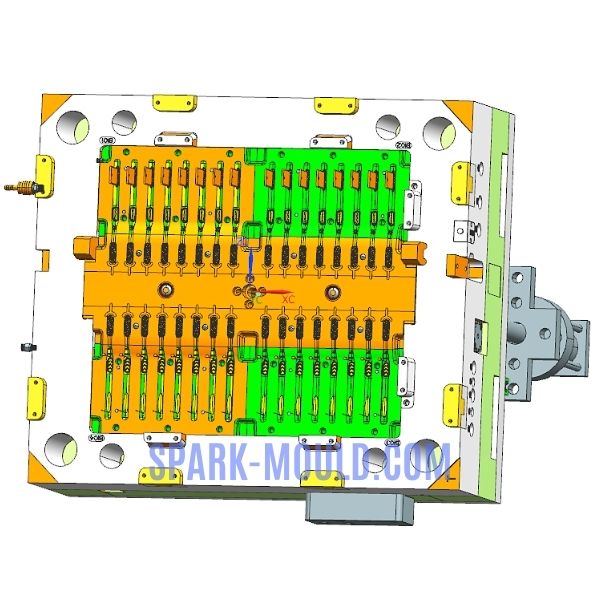

Injection Mold Design

Product Design

Reverse design existing products, or design products based on your sketches.Complete within 2-7 working days.

DFM

Analyze the manufacturability of product structure and the economics of injection molding. Complete within 0.5-2 working days.

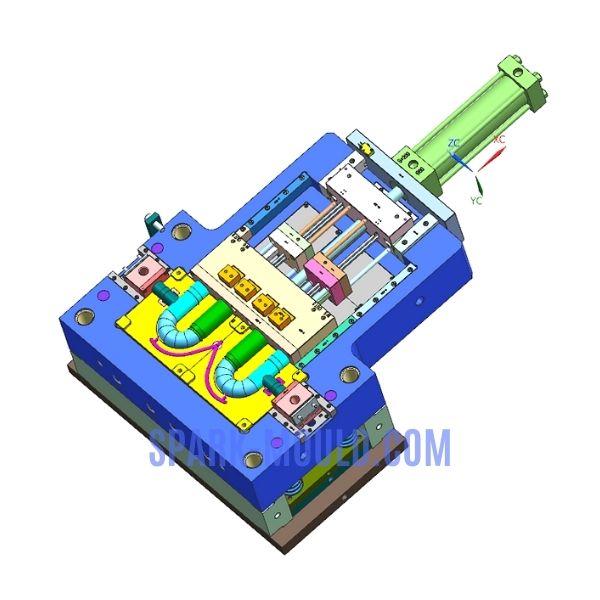

Mold Structure Design

We are proficient in DME, HASCO, MISUMI and other standards. All designers have more than 7 years of mold design experience. The drawings will be completed within 2-5 working days. And we will review the drawings before delivery.

Mold Flow

Analyze the filling, deformation, shrinkage and other parameters in the product molding process.In order to plan and deal with it in advance.

Create Value on Youtube

We share mold structure design and project experience on Youtube.

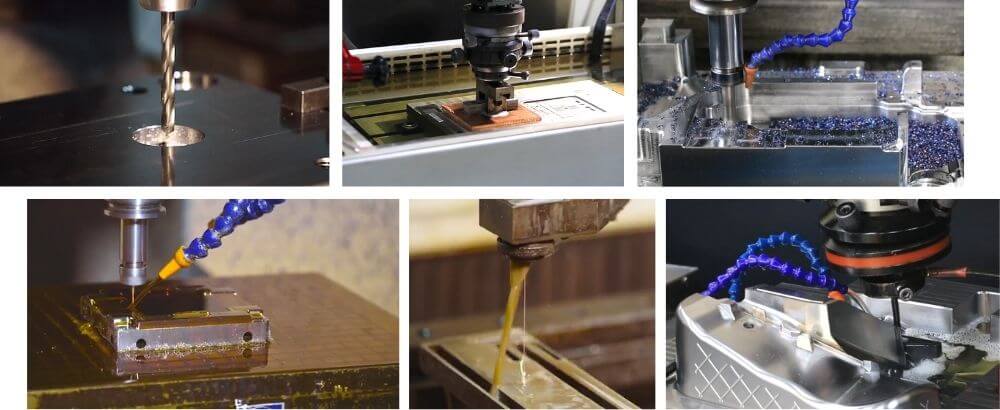

Mold Processing

Injection Mold Quality

How do we guarantee the quality of injection molds