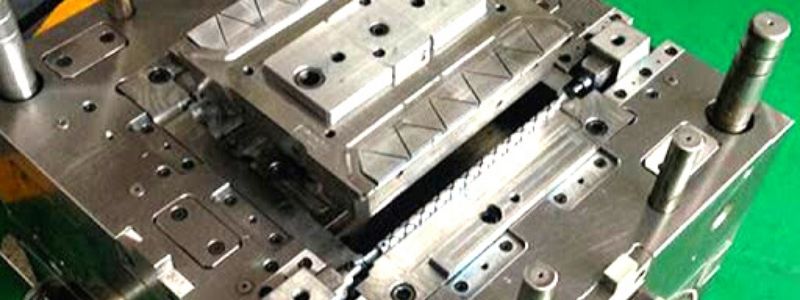

It is difficult to avoid the failure of plastic molds during use. Common failure forms of plastic molds include wear and corrosion on the cavity surface. So, what is the reason for these failures is it? For specific analysis, please refer to the following introduction.

Wear and corrosion on the cavity surface.

1.The plastic melt flows at a certain pressure in the mold cavity. The solidified plastic part ejected off the mold. Wear on the mold surface due to friction.

2.Reinforce the material produced by resin dissolution, which will cause the corrosion of the mold cavity surface.

3.Chlorine and fluorine-containing plastics will generate corrosive gases during thermal decomposition. The coating or protective layer on the cavity surface is damaged. Causes cavity surface wear and corrosion.

The mold is plastically deformed.

1.The surface pressure of the cavity of the plastic mold is large, and heating will cause deformation. Especially when small molds work in large tonnage equipment, it is easier to produce overload plastic deformation.

2.The strength and toughness of the plastic mold material are insufficient, and the resistance to deformation is low.

3.The mold cavity surface is too thin. Insufficient resistance to deformation or changes in operating temperature. These will cause dents, wrinkles, and pitting on the mold surface.

Cracks appear in the plastic mold.

1.The shape of the plastic mold is complicated. There will be many edges and thin-walled parts. Local stress concentrations can break these parts.

2.The temperature difference, thermal stress caused by structural stress, or insufficient tempering temperature. The increase in temperature causes stress changes due to partial volume expansion.

The gate is difficult to ejected off.

1.Poor smoothness of door cones and holes. Traces of the tool have not been cleaned up.

2.The material is too soft. After a period of use, the small end of the tapered hole is deformed or damaged. The spherical curvature of the nozzle is too small, so the gate material creates a rivet head here.

The guide post is damaged.

The guide post mainly plays a guiding role in the mold. This ensures that the moulding surfaces of the core and the mould cavity do not touch each other under any circumstances. And the guide post cannot be used as a force bearing member or a positioning member.

At the end.

Failure analysis of plastic mold development. Together with water temperature machine and oil temperature machine can better guide the optimization of mold steel production. Spark mould adheres to the principle of producing high-quality molds. If you have any mold problems, please contact us for support.