The cavity of the half mold is composed of two or more sliders. At the time of mold opening, the slider simultaneously achieves side parting. The stroke of the side core pulling of the half mold is generally small.

Half mold can be divided into: fixed mode Half blocks and moving mode Half blocks. Both structures have their own advantages and disadvantages, and can be used for different products.

The fixed mode half-slider structure has three advantages.

1. It takes up less space than the half slider of movable mold. Smaller injection molding machines can be used for production, saving costs.

2. Fixed mold half slider wedge uses mold A plate to fix the mold. The wedge is strong enough and does not expand easily.

3. Only need to calculate the stroke of the product undercut, without affecting the product ejection. Especially cylindrical products are pushed out by push blocks. If it is a half slider of the movable mold, the half block must be completely separated before the product can be ejected.

3 commonly used fixed-mode Half slider structures.

There are three main combinations.

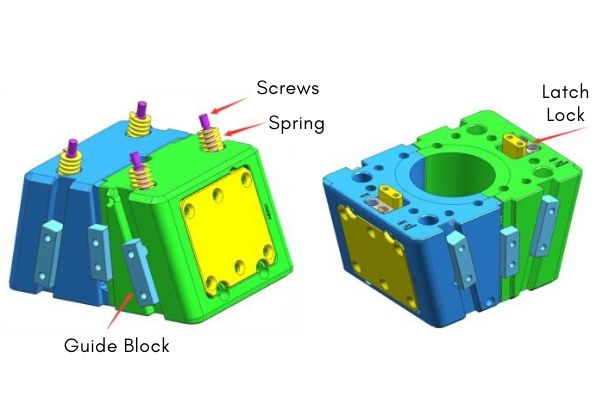

1. Latch lock + spring.

2. Latch lock + nitrogen spring.

3. Hydraulic cylinder.

Fixed mold half slider: latch lock + spring combination structure.

The main power is the latch lock, and the spring is the auxiliary function. The spring has poor stability and needs to be checked and replaced regularly. This structure is suitable for molds with relatively small sliders.

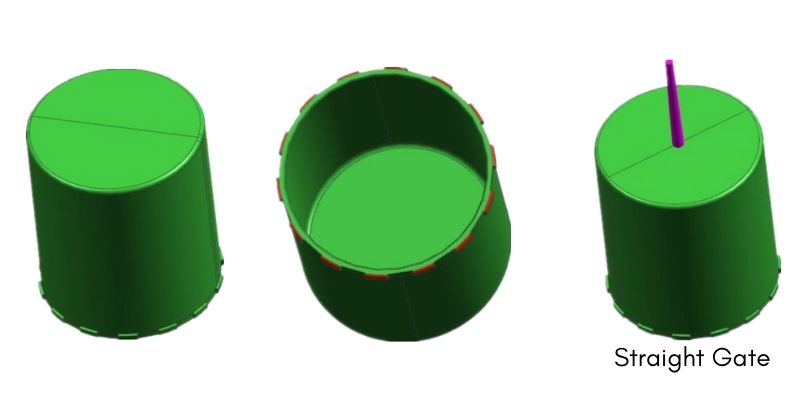

The product example is a tall cylindrical product.

The product example is a tall cylindrical product.

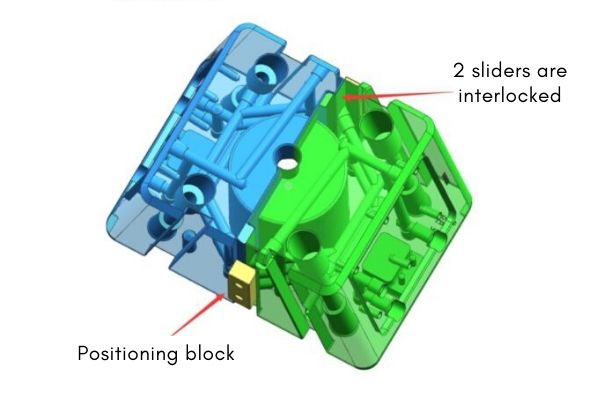

Two sliders are interlocked by slide retainer to prevent the expansion of the mold.The main function of the positioning block is to facilitate the repair of the product clamping line.

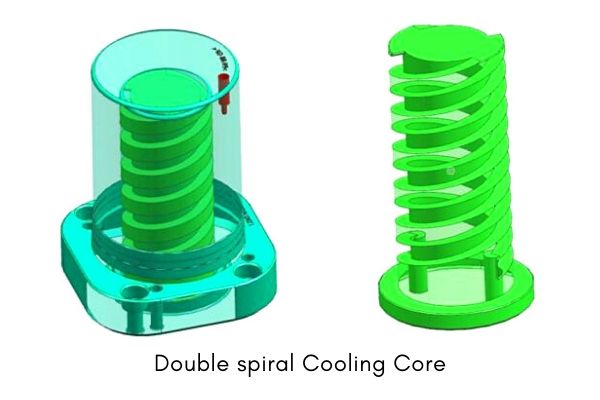

Moving die double helix cooling core.

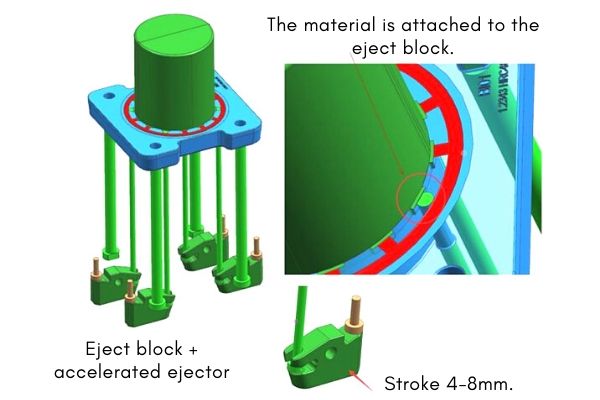

Ejection Block + Accelerate ejector.

Part of the product material is attached to the push block, so the product will stay on the ejection block after ejection. Use 4 accelerating ejector to let the product drop automatically.

This accelerated ejector ejection stroke is 4-8 mm.

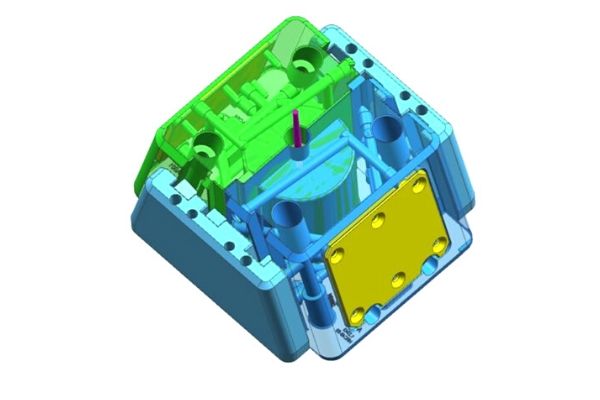

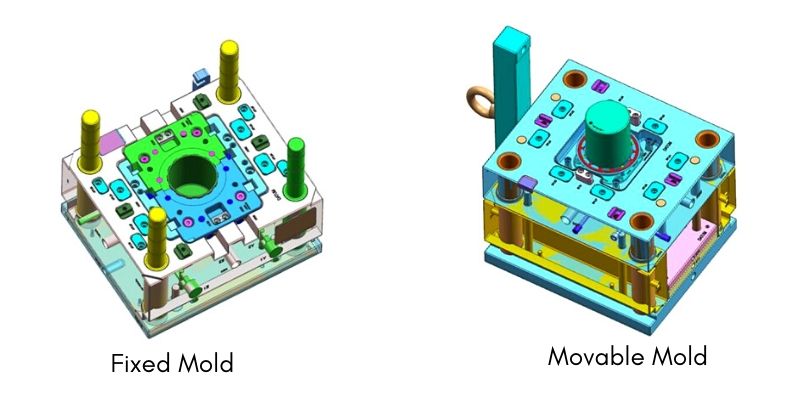

Die assembly drawing.

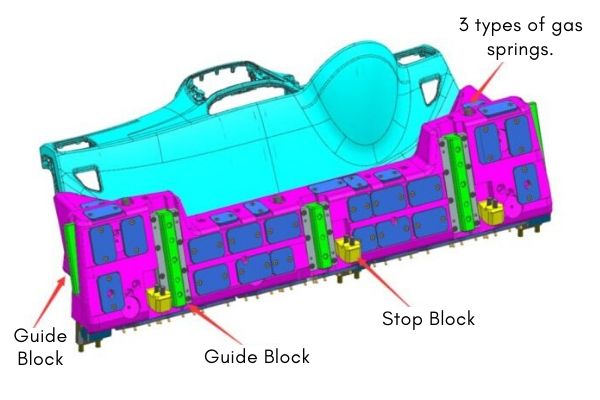

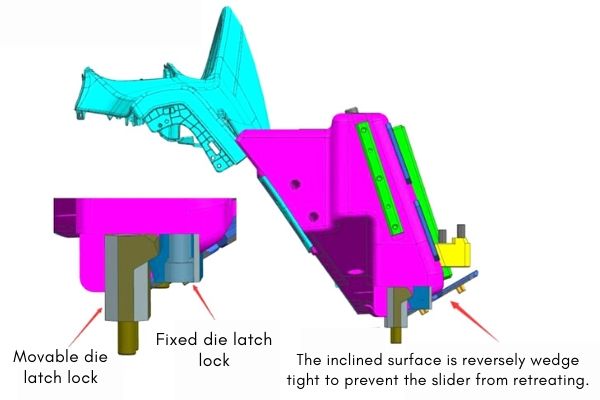

Fixed mode Half slider: latch lock + nitrogen spring combination structure.

The main power is the latch lock, and the nitrogen spring is the auxiliary function. Nitrogen springs have large elasticity and are more stable. They are suitable for larger sliders, especially large and medium-sized automobile molds. The inclined surface of the slider is used as a wedge to prevent the slider from retreating.

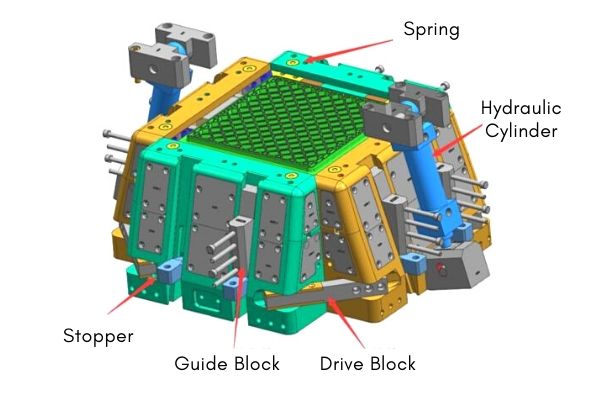

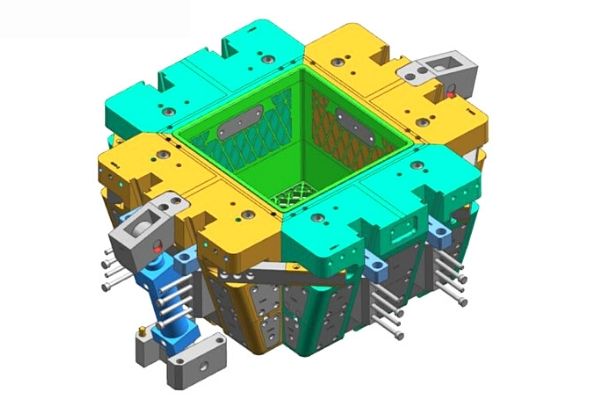

Fixed mold half slider: hydraulic cylinder drive structure.

The stability is better, suitable for the mold with a larger 4-sided inclined slider, especially the vegetable basket mold.

Precautions for the half slider in the fixed mold.

1. After the slider is separated, set a lock of 2/3 length higher than the height of the slope of the slider. Otherwise, the reset is easily stuck.

2. The oblique spring angle of the slider is less than 10 degrees and it is easy to be stuck. Due to the frictional resistance coefficient of steel, the smaller the slope, the greater the resistance. It is recommended to select 10 ~ 20 ° for the slope angle.

3. Angle method of slider guide block:

a. The angle of the guide block can be parallel to the slope of the slider.

b. The guide block angle can be 1 degree smaller than the slope. The slope angle of the slider is largely vacated first to reduce the contact area between the slope of the slider and the A plate when opening and closing the mold.

4. The pull hook installed on the rear mold should have sufficient clearance on the inclined slider (L clearance). Calculate the stroke of the slider to know the clearance height.

5. Latch lock to set the slope to reduce the wear between the slider and the moving template. Generally, C = 1.5 ~ 3°, and the assembly position must be at 3/4 of the center of gravity of the slider.

Question: Will the slider move the product obliquely?

When the mold is opened, the product and the inclined slider move synchronously back to the mold. The relative motion of the product and the inclined slider does not interfere. The principle is the same as that of the lifter synchronous ejection product. It is equivalent to another lifter with different design methods.

Conclusion.

The fixed mold half slider structure is relatively uncomplicated. In the design, pay attention to factors such as stroke, guide block, drive block and so on. The above notes can help you design better.

If you have any questions about plastic molds, please feel free to contact us for help.