Among auto molds, auto injection molds are the most common molds. In auto injection molds, there are two main distinctions. One is the exterior and interior parts of the car, and the other is the structural parts.

On the complexity of auto mold structure. The car exterior structure is headed by a bumper. Car interiors are led by instruments. Automotive structural parts should be led by automotive air conditioners and intake manifolds.

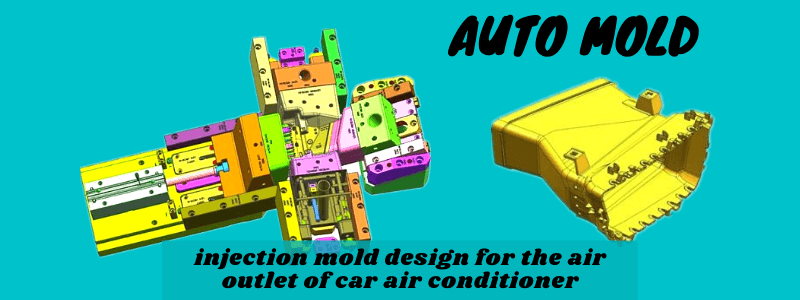

The example studied in this article is the air outlet of an automobile brand air conditioner. Let’s dive in together.

Product analysis.

The plastic parts are automobile air conditioning vents. There are many ribs and undercuts inside. The plastic material is crystalline engineering plastic PBT + PCGF10, with an average wall thickness of 2.0mm.

There are many external ribs and undercuts on the plastic parts, and the wall thickness is uneven. This is prone to injection defects such as short shots and unsatisfactory filling. Therefore, the position of the parting surface of the plastic part, the slider mechanism and the depth are the design difficulties.

Overall mold structure.

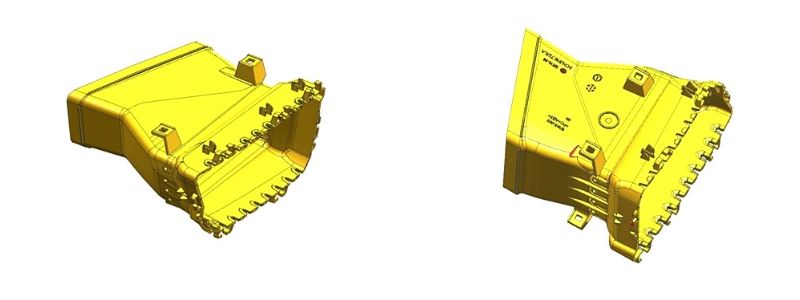

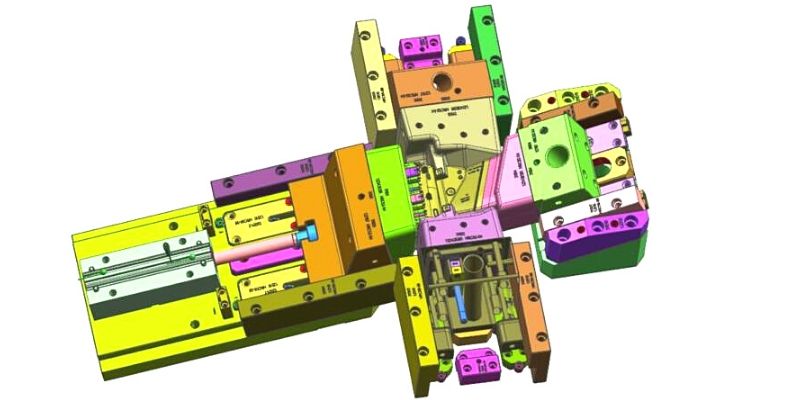

In order to improve production efficiency, this car mold adopts a 2-cavity structure. Simultaneously mold 2 plastic parts of air outlet.

The fixed mold of the auto mold.

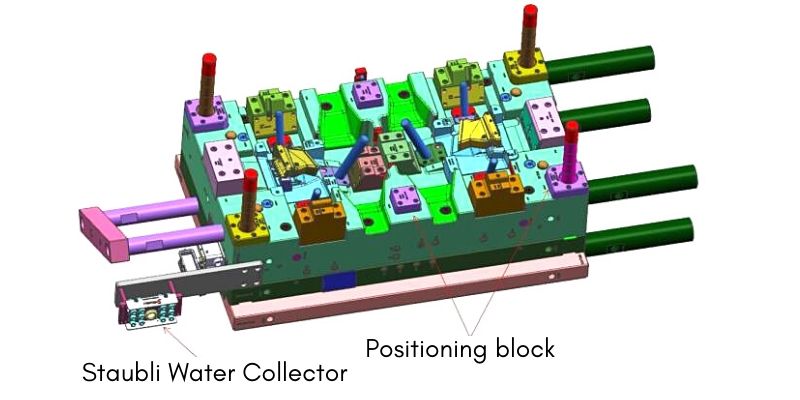

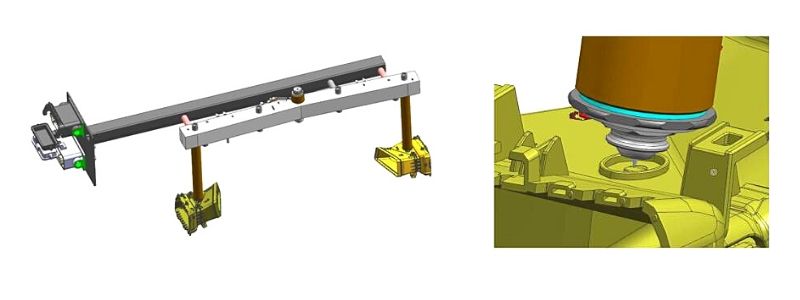

The fixed part is shown in the figure below. The staubli water collector is installed in the fixed mold. This is to adapt the customer’s injection molding machine. The angle pin is used to drive the slider. The positioning block is that there is no deviation when the mold is opened and closed. Because the mold size is relatively large.

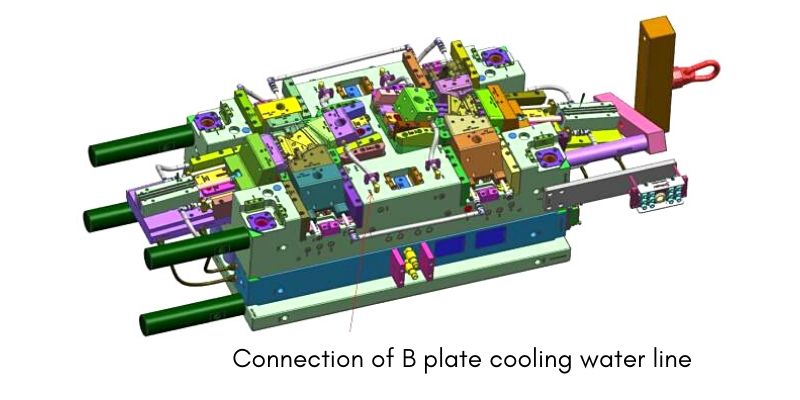

Movable mold of auto mold.

The moving mold part of the car mold is shown in the figure below. The cooling system is in the movable mold. Pay attention to the cooling water connection of the slider. Sink the B board first, and then connect from the B board. The design of the cooling water channel should try to ensure that the mold cools evenly and quickly. To shorten the molding cycle. The temperature difference between the water inlet and outlet of the mold should be <2°C.

Gate System.

The injection mold adopts hot runner valve gate system. As shown below.

Auto mold molding part.

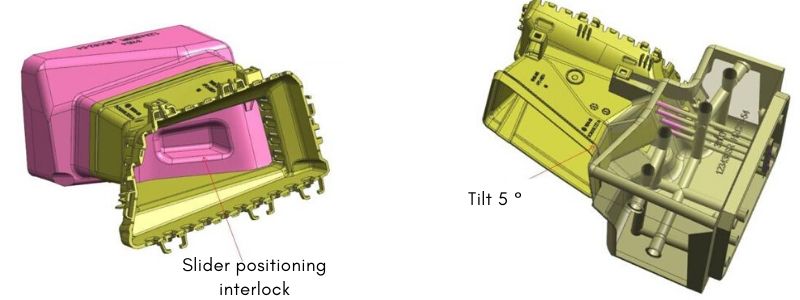

According to the characteristics of the product, there are ribs and undercuts on all four sides. And plastic parts are not straight channels. Therefore, 4-sided slider is seted. Three of the sliders are controlled by inclined guide posts. One is controlled by the cylinder.

The touch surface between the slider and the fixed mold is inclined at 5 °. The larger the angle, the better. In order to better cooperate with each other and reduce wear. As shown below.

The inner slide of the product increases positioning interlock. Prevent the slider from being misaligned. as the picture shows.

Slider Mechanism

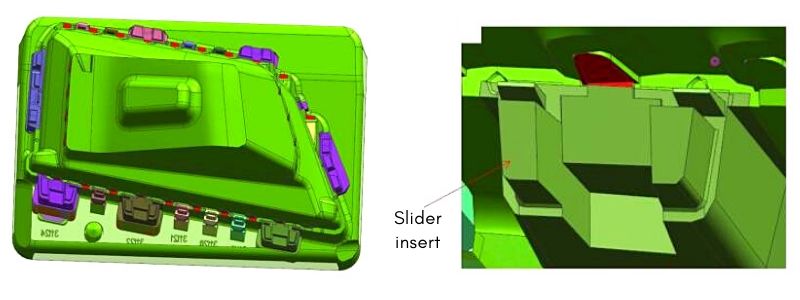

Inserts are embedded on the outside of the slider. As shown below. The benefits of this are:

1. During the EDM process, the entire slider does not need to stand up. The inserts are processed separately to reduce the processing cost.

2. The insert has a shut off surface, which is convenient for later replacement.

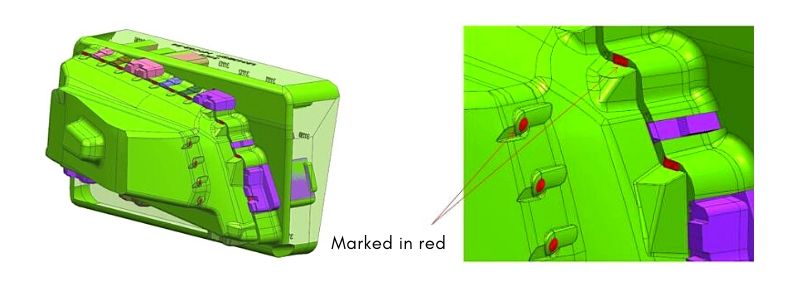

In addition, the area shown in the figure below is marked in red. Remind CNC and EMD to leave a margin during processing. These margins are used for assembly mold debugging.

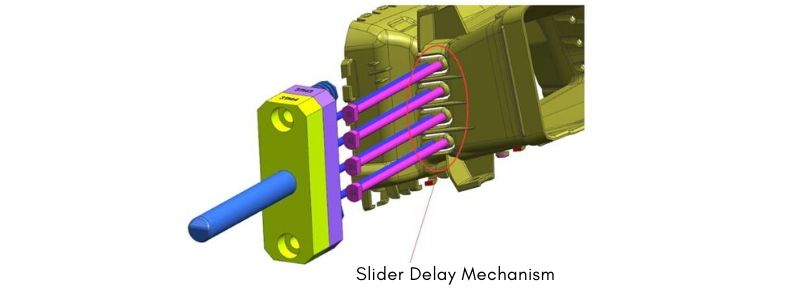

There is snaps at the side of the product. The slider is provided with a delayed ejection mechanism for inserting needles. This is to prevent the snaps of the product from being damaged by stress when the slider is detached. As shown below.

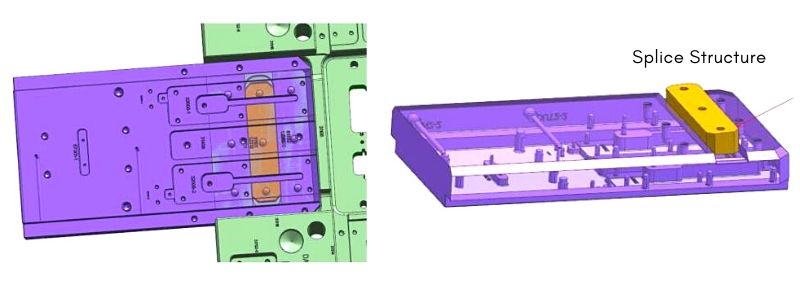

The slider base adopts a splicing structure. This can save steel and process faster. And the mating surface can be disassembled and assembled separately, which is convenient for mold matching. As shown below.

Ejector System.

The ejection system of this set of automobile molds adopts the mechanism combination of lifter and ejector.

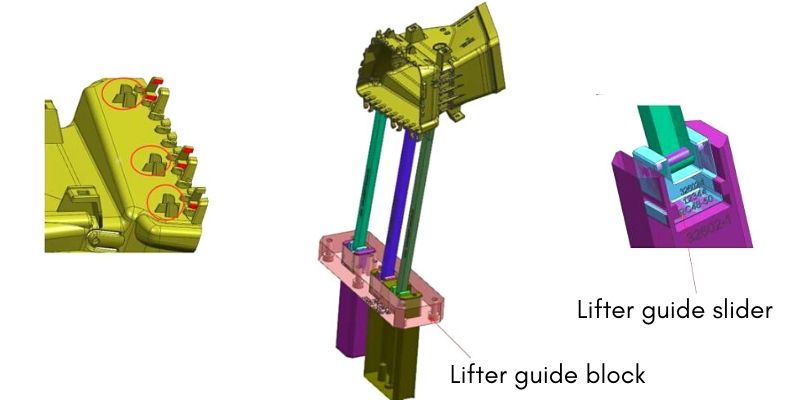

3 small lifter structures. The lifter guide design adopts the lifter base as the guide, which is simple and practical.

Conclusion.

There are many similar auto molds. The complex injection mold lies in the clever use of the mechanism. The grasp of its details is also very important.

If you have any questions about injection molds, please feel free to contact us for technical support.