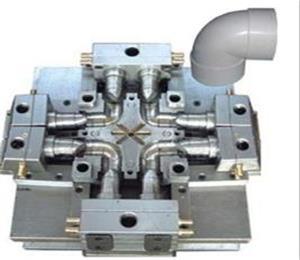

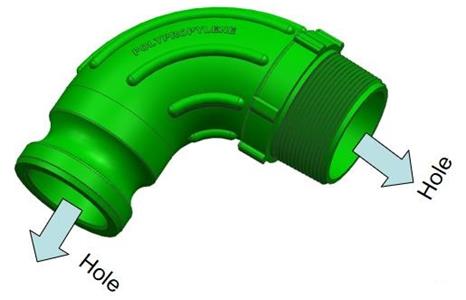

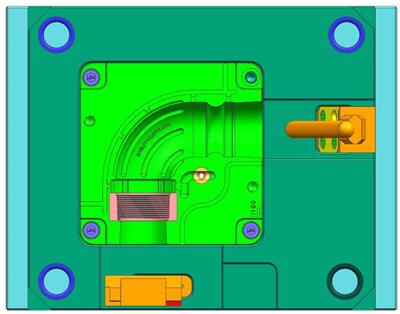

As shown above, this is our company’s recent mold project- 90 degree elbow mold . An injection mold for the production of plastic bends. For plastic elbow molds, the core structure is essential. We use the collapsible mold core, since the structural characteristics of the product different from the traditional PVC 90 degree elbow. Let’s look down.

Mold and parameters

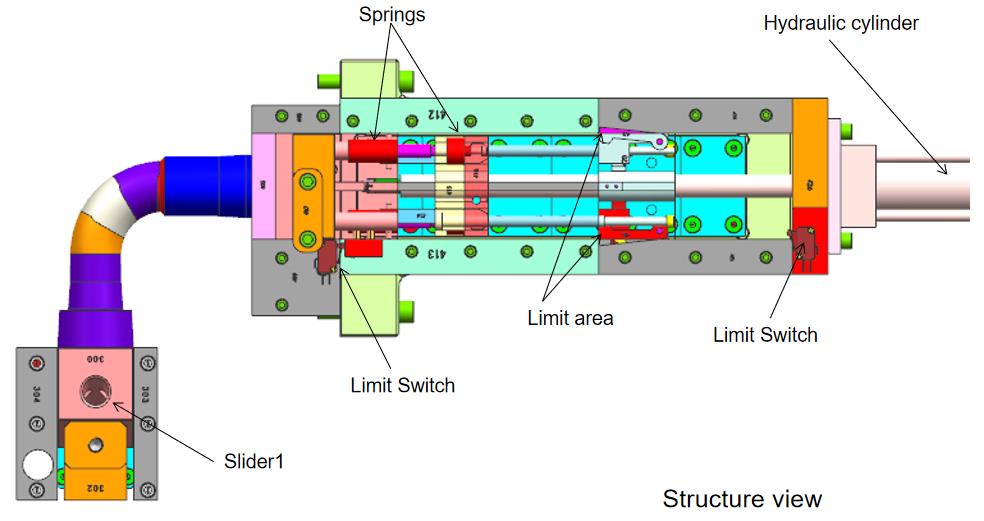

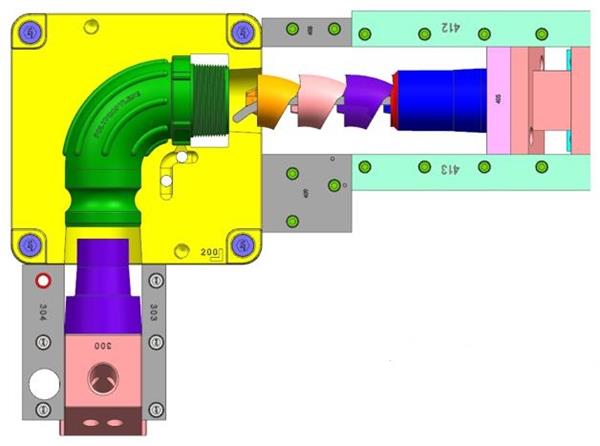

The picture above shows the overall appearance of the mold. The Mold size CI3540. How about it? It is like a big hammer. Slider and hydraulic cylinders to make it look very prominent . Take a look at some of its parameters:

| Part information | Tool information | ||

|---|---|---|---|

| Part name | 220FSWP90 | Standard | DME |

| Part NO: | Type | Two plate | |

| material | PP+25%GF | Cavity | 1*1 |

| Shrinkage rate | 1.01 | Insert steel | H13(HRC48-52) |

| Color | Black | Runner type | cold runner |

| Surface finish | Cavity :SPI B3, Core :600# Sandpaper | Gate type | Side gate |

Product Analysis

Although it is not a big guy. Its structural characteristics have caused us some trouble. Now let’s look at the product.

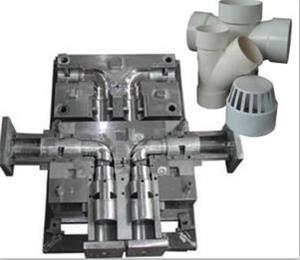

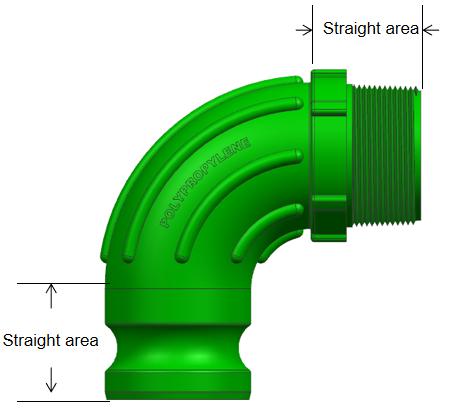

There will be two straight sides on the finished product,the slider cannot slide out directly due to the bend in the product,this is why we have to design a special mold structure for releasing the mold.

“Oh, this is a small challenge.” This is the result of thinking about our mold design for an hour. But we are happy to challenge ourselves. And we can learn some of our own cases. Before that, we also made a lot of plastic elbow molds. Including 180 degree elbow, 45 degree elbow, 30 degree elbow, tee or cross, and other plastic fittings.

The design analysis of the mold

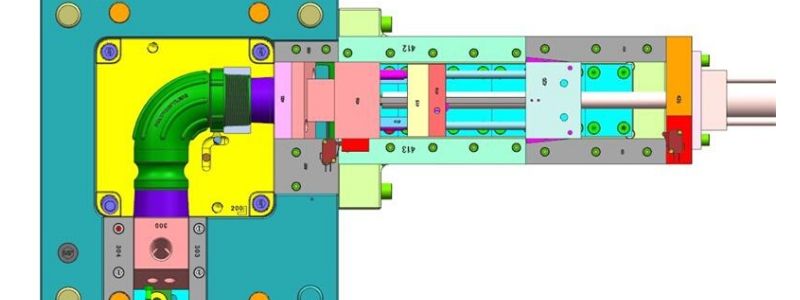

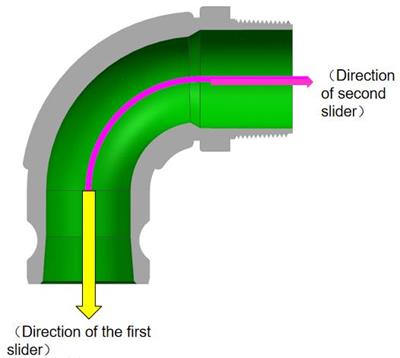

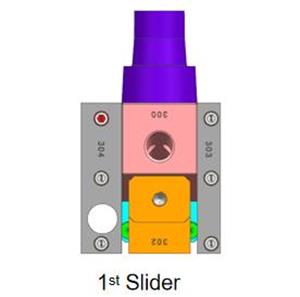

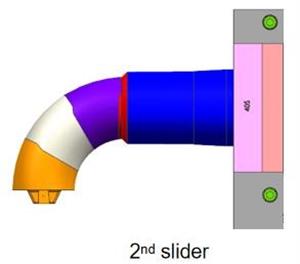

According to the product requirements,our engineering department designed an innovative mold structure to solve the issue of mold releasing. The mold will need two sliders for this product, as you can see the image to the right, the first slider is only for the straight section, the second slider needs to go straight and then rotate the core inserts out of the part.

Mold slider structure

Now let’s take a look at the overall structure of the slider:

Collapsible core

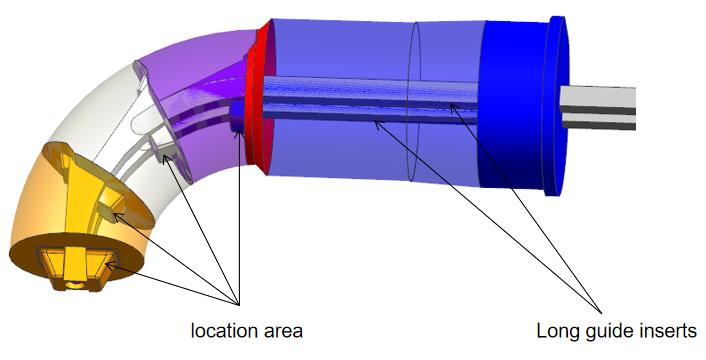

For the mold smoothly,we have to separate the Second slider into 3 core inserts. see below

The figure below shows the structure of row 2.

In fact, this variant core structure is more like a chain. Therefore it is also called chain core structure.

To make the product release from the mold smoothly ,we designed and manufactured three pivoting core inserts. It depends on the arc length of the elbow and it has two straight area.

The only disadvantage of this structure is that the mold core cannot carry cooling. Only used the method of external cooling .

Ok, let’s look down.

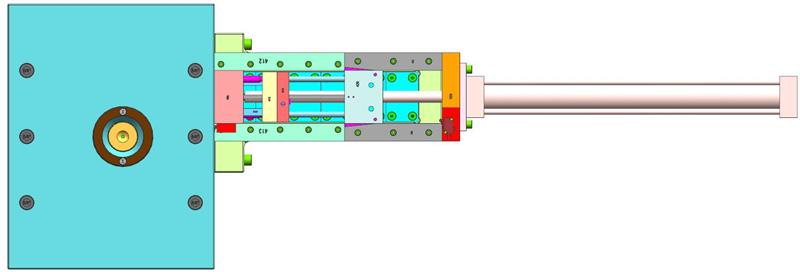

Mold fixed side and moving side

The slider comes out view. We control the entry and exit of the slider through two wire ropes.

Let’s look at the structure of the fixed side. The mold core contains a threaded insert.

Contact

I can only talk about so much about the design of the mold. We reserve more details, because the company needs. thank you for your forgiveness.

Maybe this is not the perfect solution, in fact we have succeeded. If you have a better idea, you can talk to us.

If you have a manufacturing need for a plastic elbow mold, you can contact us. We will respond to you within 1 hour.

Look down!

Practical application of the mold

Let’s take a look at the performance of the mold in practical applications. The video below is a motion demonstration of the mold slider. Collapsible core is very smooth.

The video below is the production of plastic elbows. We use a 200T injection molding machine. In order to meet the requirements of injection pressure and amount of glue.

Finally, look at the finished product.

There are no defects in the product, and no depressions inside the tube. The threads mesh well with other accessories. The word mark is very clear.

At the end

The mold took us more than 40 days to complete these things. Although it has encountered some trouble, it has been overcome. Now the mold has been officially put into production, producing 600pcs per day. Outstanding

This is just one example of our curved tube mold, and we will update more cases later. Stay tuned.

Postscript

We are professional manufacturer of plastic elbow die. Whether it is a 90 degree elbow / a 120 degree elbow / a 360 degree elbow or a variety of non-standard angle elbows. And all kinds of water pipe joint Plastic molds. We can also injection molding plastic elbows, such as PVC / pp + GF / PC + GF / PA + GF / ABS.