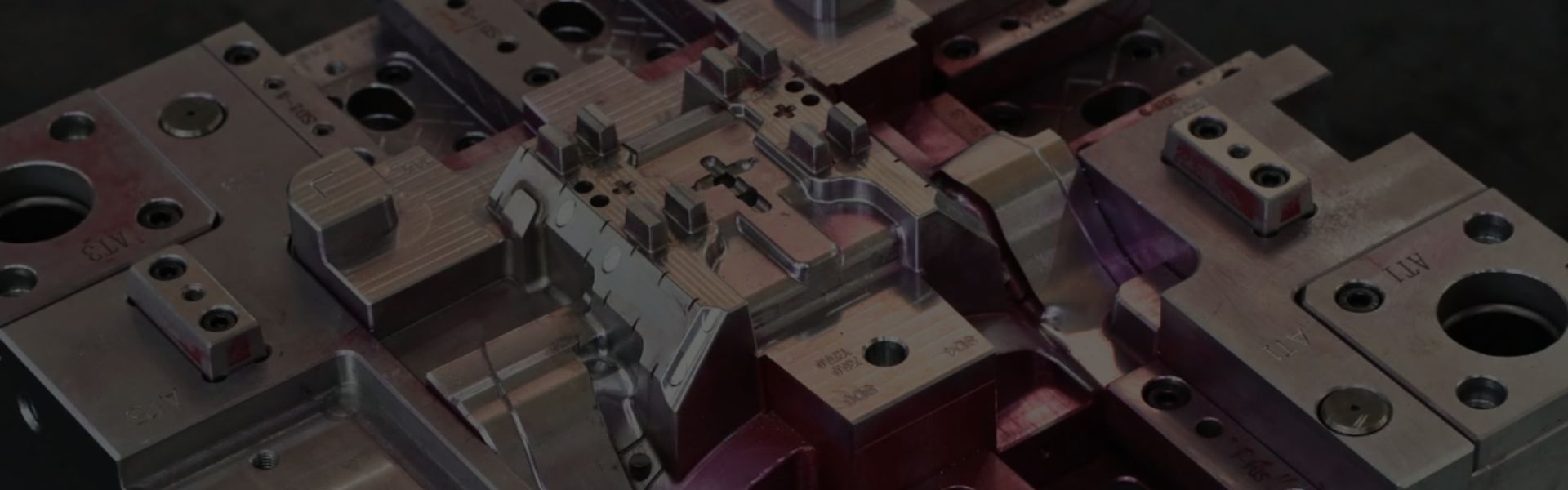

Leading Mold Manufacturer since 2005-Spark Mould

We are proficient in various injection mold structures and provide you with reasonable solutions

Free analysis consultation

Manufacturing +

We turn your designs into reality, not just the mold. Our services integrate injection molding, compression molding, and die casting. We provide you with a seamless transition from small-batch trials to full-scale production. Simplify your supply chain and speed time to market.

About Spark Mould

Spark Mold is located in Dongguan, China, and specializes in injection mold manufacturing and injection molding. We are committed to providing one-stop, customized mold solutions for global brands and manufacturers.

Our customer base covers many fields such as automobiles, consumer electronics, home products, plumbing systems, etc. We rely on our 20 years of industry experience to meet the growing and diverse needs of our customers. Our team members have deep mold manufacturing expertise, rich practical experience and innovative thinking.

They continue to learn new technologies and processes, and maintain a keen insight into industry trends. It is this high-quality technical team that has won the trust of customers and recognition from the industry for our company.

How to manage your project remotely

Detailed project timeline and key node control.

We will provide a detailed project timeline, clearly marking the time nodes of each stage. Send project progress reports regularly every week to ensure that customers can keep abreast of the latest progress and completion of the project.

Intuitive information feedback form to show the actual situation of the project.

We will use various forms of information feedback such as pictures and videos. Let customers feel every step of the project more realistically and enhance the transparency and credibility of the project.

Direct connection with professional project managers, barrier-free communication.

Customers will directly connect with experienced, professional and responsible project managers. Even if customers do not understand injection molds, they can ensure that customers have a clear grasp of the overall situation of the project.

Injection Mold Quality Control

Customers give us high praises, and our quality and service are both online! Every positive review is the best proof of our professionalism and dedication.

Get In Touch With Us

We'd love to hear from you! This form connects you straight to our engineers for a quick and professional response.