Moulds are intermediate products in the production process. It is the tool used to produce the final product. Mold processing is one of the important ways of material forming. It has the advantages of high material utilization, easy production and high efficiency. Therefore, it is widely used in the production of automobile, machinery, electronics, aerospace industry and daily necessities.

Development history and trends of injection mold.

As early as 2000 years ago, the ancients already had the concept and application of molds. The world’s first injection molding machine was born in 1872. The injection mold develops with the development of the injection molding process. To date, the manufacturing technology of injection molds has reached a mature stage.

With the gradual transformation and upgrading of the industrial structure. Although the output growth of plastic products has slowed down, its value space is still large. The output value can maintain a high growth rate.

Upstream and downstream industries of injection mold.

1.Upstream industry-mold steel manufacturers.

Mold steel is the main part of the core of the injection mold. Its price accounts for about 25% of the total cost of the mold. The development of mold steel has a greater impact on the development of the precision plastic mold industry. The quality of mold steel has promoted the development of precision plastic mold products to high precision and high added value.

2.Upstream industry-CNC machine tools.

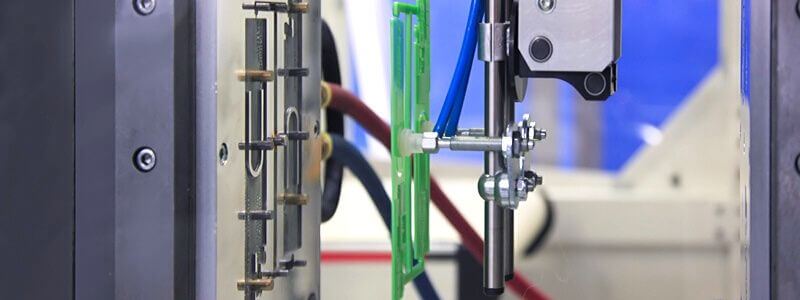

CNC machine tools are the main processing equipment in the precision plastic mold industry. CNC machine tools can effectively shorten the mold manufacturing cycle and reduce mold production costs. At the same time, due to the high price of CNC machine tools, its proportion in fixed assets of enterprises in the industry is relatively large. The vigorous development of the CNC machine tool industry has brought rise in machining accuracy and machine tool prices. This has an important role in promoting the development of the mold industry.

3.Upstream industry–plastic materials.

PC materials, ABS, HIPS, PP, PET and other engineering plastics are the main materials for precision plastic mold industry product molding. They not only have a direct impact on the quality of injection molded products. The adequacy of its supply also greatly affects the production of mold injection products. The supply and price of plastic raw materials have a direct decisive effect on the output and price of injection molded products.

4.Downstream industry

The needs of downstream industries determine the development of the mold and plastic products industry. Because mold products cannot be used for final consumption, demand depends on market demand for downstream industry products. Therefore, the needs of downstream industries determine the development of the mold industry. However, the development of the mold industry is not determined solely by the needs of an industry. It is determined by the development of the entire market economy.

Barriers to the injection mold industry.

1.Barriers of scale.

To become a comprehensive mold manufacturer requires a lot of money. Used to purchase machinery and equipment, and to introduce professional and technical personnel. At the same time, precision equipment mold company’s service targets are mainly large companies. Large companies often have larger business scales. This requires that mold companies, as an important link in their supply chain, must have a large production scale. Only by realizing production scale can we effectively reduce procurement costs and production costs.

2.Technical barriers.

The mold industry needs strong technical strength. From product 3D design, to mold making, injection molding, assembly and surface treatment. These processes affect each other and are cumbersome. Therefore, mold processing technology, quality control level and production management technology are all very important.

3.Qualification Barriers.

Large manufacturers have stricter standards for qualifying suppliers. In addition to meeting industry standards, it is also necessary to pass strict supplier qualification certification. Once the qualification of a qualified supplier is identified, manufacturers usually do not easily change the mold supply channels. Stable supply and demand relationship based on long-term cooperation. It has formed a very strong qualification barrier for newly entered enterprises.

At the end.

With the technological progress and consumption upgrade, the plastic products industry will still develop steadily. A new era has arrived, and the mold industry has ushered in new opportunities. The future can be expected to move forward.

If you have questions about injection molds, please contact us for assistance.