In which industries is the bend tubes used?

Many industries use bend tubes technology.For example: boiler and pressure vessel industry, central air-conditioning manufacturing, automotive industry, aerospace industry, shipbuilding and other industries.The quality of the bend tubes pipe will directly affect the structural rationality, safety and reliability of the products in these industries.Therefore, in order to bend tubes high-quality pipe fittings, it is necessary to master the processing skills of the pipe fittings under different process conditions.

For cold bends, it is necessary to properly select the core rod and master its correct use.

How to choose cold bending process of tubes?

In general, cold bends are available in two ways: one is a coreless bend and the other is a cored bend.Then the problem is coming.Under what circumstances do you use a coreless bends, when do you use a cored bends and what kind of mandrel to use when you have a cored bends?It is necessary to analyze the relative bending radius R/D of the bent pipe and the magnitude of the relative wall thickness S/D and the bending angle α.Can refer to the table below:

| R/D>= | 1 | 1.5 | 2 | 2.5 | 3 | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| bend angle α | 90 | 180 | 90 | 180 | 90 | 180 | 90 | 180 | 90 | 180 |

| S/D | bend way | ||||||||||

| 0.1 | H | H | H | H | H | H | H | H | N | N |

| 0.05 | H | H | H | H | H | H | H | H | N | N |

| 1/3 | F-2 | F-3 | F-2 | F-3 | F-2 | F-2 | H | F-2 | H | H |

| 0.025 | F-3 | F-3 | F-3 | F-3 | F-3 | F-3 | F-2 | F-2 | H | H |

| 0.02 | F-3 | F-4 | F-3 | F-4 | F-2 | F-3 | F-2 | F-3 | F-2 | F-2 |

| 1/6 | F-4 | F-5 | F-4 | F-5 | F-3 | F-4 | F-3 | F-4 | F-2 | F-3 |

| 1/7 | F-4 | F-5 | F-4 | F-5 | F-3 | F-4 | F-3 | F-4 | F-3 | F-4 |

Need to pay attention to:

- R is the relative bending radius;D is the outer diameter of the pipe;S is the wall thickness

- N—— It represents a coreless bend;

- F—— It represents a soft mandrel bend;

- H—— It represents a hard mandrel bend;

- The number after the letter represents the number of spheres

Process analysis

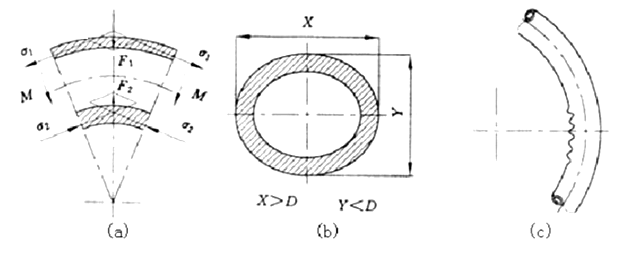

In the case of pure bending.When the pipe having the outer diameter D and the wall thickness S is bent by the action of the external moment M, the pipe wall outside the neutral layer is thinned by the tensile stress σ1, and the inner pipe wall is thickened by the compressive stress σ2.At the same time, the resultant forces F1 and F2 deform the cross section of the pipe to become approximately elliptical.The inner tube wall may also be unstable and wrinkled under the action of σ2.

In order to bend the ideal pipe fittings, corresponding measures should be taken to prevent the occurrence of these defects.Among them, the core bend is one of the most commonly used effective methods.

Cold bending tube mold composition

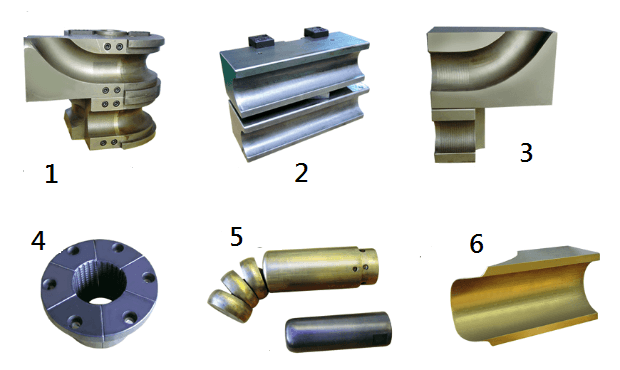

Cold-bending pipe molds generally have the following parts:

1.Diameter die 2.Guided mold 3.Clamping 4.Bunch head 5.Dredge mandrel 6.Post-guided mold

The video about cold-bending

We often have content updates about the mold. If you are interested.We would like to you to follow us.

If you need to talk to us online. Click on the right side Service. Or email contact us