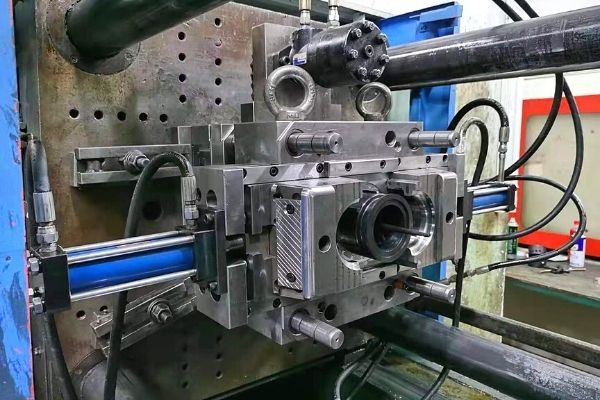

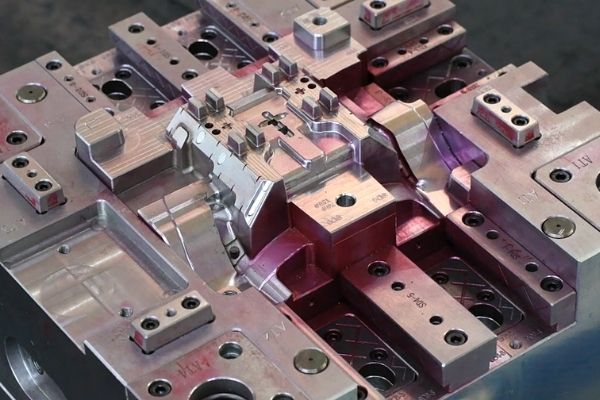

Professional Injection Mold Manufacturer

& Injection Molding

·20+ years of industry experience.

·Focus on quality and service.

Professional Injection Mold Manufacturer

& Injection Molding

·20+ years of industry experience.

·Focus on quality and service.

About Us

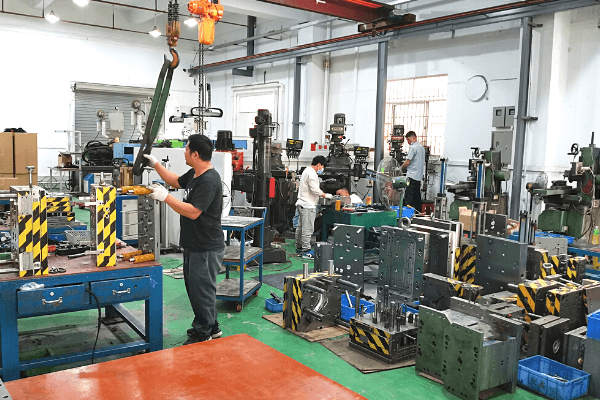

Spark Mould Technology Co., Ltd. is located in Chang’an Town, Dongguan City, China. Chang’an Town is the hometown of moulds in China. We have worked hard here for nearly 20 years.

In 2003, we were established here. At that time, it was just a small mold workshop with only 3 employees. Up to now, we have a 2000 square meter factory. The number of employees reaches 52.

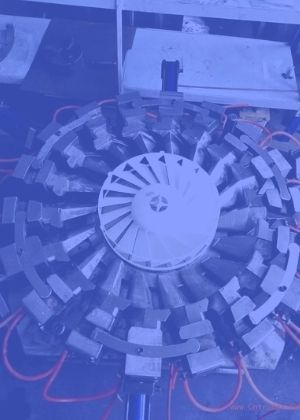

We have served 200+ customers worldwide. Since its establishment, we have implemented the concept of innovation and quality. This is why we can maintain long-term cooperation with our customers. We have grown up with our customers, and we have also witnessed the growth of some customers. These are extremely precious in our history.